Struggling to find a simple, strong, and reliable way to mount or hold metal objects without damaging surfaces or drilling holes? Pot magnets might be the exact solution you need. These compact yet powerful magnets—often made with neodymium or ferrite and encased in a steel housing—deliver intense holding force while protecting both the magnet and the surface it grips. Whether you’re a DIY enthusiast organizing your workspace or a professional tackling industrial clamping, understanding what pot magnets are used for opens up a world of hassle-free mounting, lifting, and fixing possibilities. In this guide, we’ll break down their key applications and explain why they’re becoming indispensable tools in workshops, homes, and manufacturing floors alike.

What Is a Pot Magnet A Quick Breakdown of Design and How It Works

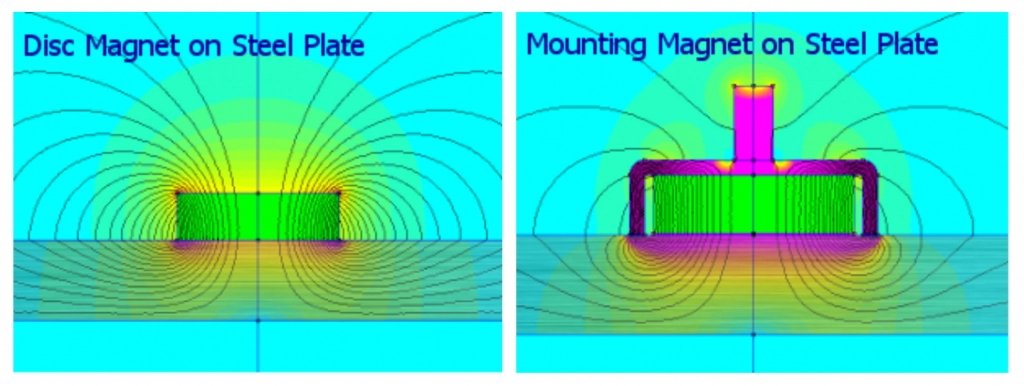

A pot magnet is a powerful type of magnet housed inside a steel shell, designed to concentrate magnetic force in a small area. At its core, it features a strong magnet—often neodymium or ferrite—encased within a steel pot or housing. This steel housing plays a critical role by directing the magnetic flux, which significantly enhances the holding force compared to a bare magnet.

The steel pot not only protects the magnet from damage but also focuses the magnetic field toward one side, increasing grip strength on ferrous surfaces. Many pot magnets come with optional features like threaded holes or rubber coatings to improve mounting options and surface protection.

Pull force ratings for pot magnets can reach up to 130 kilograms, but actual strength depends on several factors:

- Thickness and type of the surface it attaches to

- Temperature conditions that may affect magnetic performance

- How clean and flat the contact area is, ensuring maximum contact and holding power

This combination of magnet core and steel housing makes pot magnets a versatile and reliable solution for strong magnetic holding in many applications.

Key Benefits of Pot Magnets Why They Are a Game Changer for Holding and Mounting

Pot magnets stand out because they pack a strong magnetic holding force in a compact design. Thanks to the steel housing—or “pot”—these magnets concentrate magnetic flux, giving you higher pull strength than a bare magnet of the same size. This strength and efficiency mean you get a smaller magnet that does more work, saving both space and money.

Durability is another big plus. The steel shell protects the magnet core from chipping and damage, making pot magnets much tougher in everyday use. Many also come in weatherproof options, so they hold up outdoors or in damp environments without losing power.

They’re incredibly versatile and easy to install, often featuring threaded mounting options or countersunk screws for a secure fit. Plus, pot magnets work best on ferrous metals, providing safe and reliable clamping without slipping.

NBAEM’s premium NdFeB pot magnets take this to the next level with unbeatable strength and consistent performance, making them a top choice for everything from industrial use to home projects. For more on magnet types and materials, check out this magnet material guide.

Industrial and Professional Uses Pot Magnets in Action

Pot magnets are a staple in many industrial and professional settings because of their strong holding power and reliability. Here’s how they’re commonly used:

Clamping and Fixturing

- Secure workpieces firmly during welding or machining

- Hold metal sheets steady on assembly lines, making fabrication faster and safer

- Ideal for industrial clamping applications where stability matters

Mounting and Signage

- Attach displays, sensors, and lights to steel frameworks without drilling

- Perfect for mounting magnetic downlights in ceilings or temporary signage

- Threaded mounting magnets allow quick installation and repositioning

Lifting and Retrieval

- Deep pot magnet variants are great for magnet fishing and metal retrieval

- Handy for picking up screws, nails, and other small metal parts in tight or out-of-reach spots

- Save time and reduce injury risk by avoiding hand searching in messy work areas

Specialized High-Temperature and Corrosion-Resistant Uses

- Alnico pot magnets withstand high temps, perfect for welding jigs and hot environments

- SmCo magnets offer excellent corrosion resistance for marine and outdoor industrial uses

- Ferrite and rubber coated pot magnets provide weatherproof options for harsh conditions

Real World Example and NBAEM Product Fit

- NBAEM’s premium NdFeB pot magnets deliver powerful magnetic flux concentration, ideal for heavy-duty clamping and mounting

- Their corrosion-resistant coatings suit marine and outdoor industrial applications well

- Modularity in threaded and countersunk options lets pros customize based on project needs

Pot magnets truly shine wherever strong, reliable magnetic clamping, mounting, or lifting is needed in industrial or professional settings.

Everyday and DIY Applications Simple Ways Pot Magnets Simplify Life

Pot magnets are incredibly handy around the house and for DIY projects. They offer simple, effective solutions for organizing, securing, and attaching items without the need for nails or screws. Here’s how you can use them every day:

Home Organization

- Hang tools, mugs, or even kitchen utensils on your fridge or any steel door using threaded hooks attached to pot magnets.

- Use them inside cabinets or closets to keep metal items neat and accessible.

- Magnetic storage racks made with pot magnets can hold scissors, keys, or small metal parts without clutter.

Crafts and Hobbies

- Pot magnets are great for model building, helping hold pieces together temporarily during assembly.

- Secure banners or signs at events with rubber coated pot magnets to avoid scratching surfaces while providing a strong, stable hold.

- Their scratch-free grip is ideal for delicate or finished materials where you don’t want damage.

Automotive and Biking

- Attach lights or pedals to bike frames quickly without permanent mounts, perfect for seasonal gear changes.

- Extendable pickup tools with pot magnets help grab screws, nails, or dropped metal parts in hard-to-reach places.

- Mechanics benefit from magnetic trays using pot magnets to keep small metal components secure while working.

Practical Tips for Everyday Use

- Choose rubber coated pot magnets for scratch-sensitive surfaces.

- Use affordable ferrite pot magnets from NBAEM for hobby projects where extreme strength isn’t critical.

- Position magnets carefully to maximize their holding force by ensuring full contact against smooth, clean ferrous surfaces.

- Combine threaded or countersunk pot magnets with hooks or holders to customize your setup.

With their compact size and strong magnetic holding force, pot magnets make life easier, whether you’re organizing your home, crafting, or handling automotive repairs. For those interested in learning more about the different types and magnetic materials, check out NBAEM’s guide on soft magnetic materials vs hard magnetic materials.

Choosing the Right Pot Magnet Types and Selection Tips

Picking the right pot magnet can make all the difference for your project, whether it’s industrial, DIY, or professional use. Here’s a quick overview of the most common types and what to look for:

Common Pot Magnet Types

- Countersunk magnets: Great if you need a flush mount with screws.

- Screwable and threaded magnets: Easy to install and remove, perfect for adjustable setups.

- Internal vs. external thread: Choose based on your mounting needs and hardware compatibility.

- Flat and deep pot magnets: Flat types work for thin surfaces, while deep pots give you extra holding power.

- Rubber coated pot magnets: Ideal for protecting delicate surfaces and adding extra grip.

Selection Tips

- Match magnet type to your use: For max strength and efficiency, NdFeB (Neodymium) pot magnets stand out. Ferrite ones are budget-friendly and weather resistant, great for outdoor use.

- Consider size and surface: Bigger magnets aren’t always better — thin or rusted surfaces reduce magnetic force, so test before committing.

- Watch temperature limits: High-temp pot magnets (like Alnico or SmCo) are needed for heat-intensive tasks.

- Think about the environment: Outdoor applications benefit from weatherproof or rubber-coated options to resist corrosion and wear.

Common Pitfalls to Avoid

- Using magnets on surfaces that are too thin, which lowers pull force drastically.

- Ignoring rust or moisture, which blocks magnetic contact and damages magnets over time.

- Overlooking temperature ratings — neodymium magnets lose strength if exposed to high heat constantly.

Pot Magnet Comparison Table

| Magnet Type | Pull Force Range | Best For | NBAEM Model Example |

|---|---|---|---|

| Countersunk Steel | Up to 130kg | Secure flush mounting | NBAEM NdFeB Countersunk |

| Threaded (Internal) | 20-100kg | Adjustable installations | NBAEM Threaded NdFeB |

| Rubber Coated | 10-80kg | Scratch-free surface grip | NBAEM Rubber Pot Magnet |

| Deep Pot Magnets | 50-130kg | Holding thicker metals | NBAEM Deep NdFeB Magnet |

| Ferrite Pot Magnets | 5-50kg | Outdoor, budget-friendly | NBAEM Ferrite Pot Magnet |

If you’re unsure which magnet fits your needs best, NBAEM offers customization and expert support to help you get the perfect match. Visit their site for more on magnetic materials and ways to optimize your setup.

Frequently Asked Questions About Pot Magnets

Can pot magnets be used outdoors

Yes, but it depends on the type. Pot magnets with weatherproof coatings or made from corrosion-resistant materials like Alnico or SmCo are better for outdoor use. Neodymium magnets are strong but can rust if not properly coated. Always check for weatherproof features if you need outdoor durability.

What’s the difference between neodymium and ferrite pot magnets

Neodymium pot magnets offer the highest magnetic holding force and are smaller and lighter. Ferrite magnets are less expensive, have moderate strength, and resist corrosion better. Your choice depends on your budget and how strong your magnet needs to be.

Are pot magnets safe to use on all metal surfaces

Pot magnets only work on ferrous metals like steel and iron. They won’t stick to aluminum, copper, or plastic.

How do I know the right size and pull force for my project

Consider the surface thickness, temperature, and how much weight the magnet needs to hold. For heavier loads, choose a pot magnet with a higher pull force rating, often listed in kilograms or pounds.

Can I screw into pot magnets

Yes, many pot magnets come with threaded holes or countersunk designs for easy mounting with screws or bolts.

Where can I find more information or custom options

Brands like NBAEM offer detailed specs and support for customizing pot magnets based on your needs. Check their website or contact customer service for guidance.

If you want to dive deeper, look for guides on neodymium cup magnets, industrial clamping applications, and rubber coated pot magnets for scratch-free uses.

Leave A Comment