Overview of SmCo Magnets What are SmCo Magnets General Properties that Make SmCo Magnets Desirable

SmCo magnets

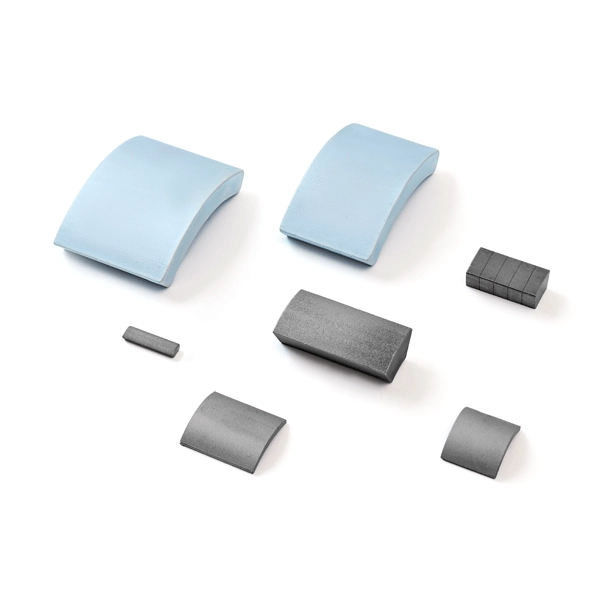

If you’re looking for high-performance permanent magnets, SmCo magnets(Samarium Cobalt) are a top choice. SmCo magnets fall under the category of rare earth magnets known for their excellent magnetic strength, thermal stability, and corrosion resistance.

SmCo magnets are made from an alloy of samarium and cobalt, which makes them standout rare earth magnets alongside neodymium magnets. What makes SmCo magnets particularly attractive is their ability to maintain strong magnetic properties even at very high temperatures—often up to 350°C (662°F). This makes them ideal for applications where heat can degrade other magnets.

Here are the general properties that make SmCo magnets highly desirable:

- High magnetic strength: Strong magnetic fields for powerful performance in compact sizes

- Excellent temperature stability: Retain magnetism at temperatures well above standard magnets

- Corrosion resistance: Naturally resistant to oxidation, usually not requiring additional coatings

- High coercivity: Resist demagnetization forces better than many other magnet types

- Long-term reliability: Maintain magnetic properties over extended periods without performance loss

Thanks to these qualities, SmCo magnets are widely used in demanding industries like aerospace, defense, electronics, medical devices, and high-performance motors. Their ability to perform reliably in harsh environments makes them invaluable where safety and precision matter.

Detailed Description of SmCO magnets: SmCo5 Magnets

SmCo5 magnets are made primarily from samarium (Sm) and cobalt (Co) with a 1:5 atomic ratio. This chemical composition gives them a hexagonal crystal structure, which is key to their strong magnetic behavior. The stable crystal lattice provides high magnetic anisotropy, helping SmCo5 magnets retain their magnetism even under harsh conditions.

When it comes to magnetic properties, SmCo5 magnets have a high coercivity, meaning they resist demagnetization well. They typically offer a strong magnetic energy product ranging around 16 to 25 MGOe, which makes them excellent for permanent magnet applications needing reliability. They also perform well at high temperatures, holding their magnetic strength up to about 550°F (290°C).

The manufacturing process of SmCo5 magnets usually involves melting the samarium and cobalt together, followed by powdering, pressing, sintering, and then aging or heat-treatment to optimize magnetic properties. This process is more straightforward compared to Sm2Co17 magnets, which require additional alloying elements and complex heat treatments.

Physically, SmCo5 magnets are hard and brittle but have excellent corrosion resistance, so they often don’t need extra protective coatings in most environments. They come in a variety of shapes and sizes, but their brittleness limits some design options compared to other magnet types.

Common uses for SmCo5 magnets include precision instruments, small motors, sensors, and aerospace components where strong magnetic performance and temperature stability are critical. Thanks to their balance of durability and magnetic strength, SmCo5 magnets are favored where long-lasting, dependable magnetism is needed without the risk of rapid demagnetization.

For more on magnet shapes that work well with SmCo magnets, check out our page on different shape of magnet.

Detailed Description of SmCO magnets: Sm2Co17 Magnets

Sm2Co17 magnets belong to the samarium-cobalt family but differ significantly from SmCo5 in chemical composition and structure. These magnets are made primarily of samarium and cobalt with additional elements like iron, copper, and zirconium that improve their performance. Their crystal structure is more complex, featuring a rhombohedral phase that enhances magnetic strength and overall stability.

Compared to SmCo5, Sm2Co17 magnets offer higher magnetic energy and better resistance to demagnetization. They typically have a stronger magnetic field and greater maximum energy product, making them ideal for demanding applications where magnetic power and thermal stability are critical. This increased strength comes from their advanced microstructure, which allows them to handle higher temperatures—up to about 750°F (400°C)—without losing magnetism.

Manufacturing Sm2Co17 magnets is more complex and time-consuming than producing SmCo5. The process involves precise heat treatments and alloying steps to control phase formation and grain size. This complexity ensures the superior magnetic performance and temperature resistance of Sm2Co17 magnets, but it also adds to production costs.

Physically, Sm2Co17 magnets are brittle but offer excellent corrosion resistance, reducing the need for protective coatings in most industrial environments. Their durability and stability under harsh conditions make them a popular choice in aerospace, military, and industrial motors where both performance and reliability are essential.

Common applications for Sm2Co17 magnets include high-performance electric motors, sensors, and aerospace systems where high temperature tolerance and strong magnetic force are required. They also find use in renewable energy technologies like wind turbines, where their stability under variable temperatures is a key advantage.

For those interested in different magnet shapes and sizes for custom solutions, check out our guide on different shapes of magnets.

Key Differences Between two SmCO magnets : SmCo5 and Sm2Co17 Magnets

When choosing between SmCo5 and Sm2Co17 magnets, understanding their key differences helps match the right magnet to the application. Here’s a straightforward comparison of their main features:

| Feature | SmCo5 | Sm2Co17 |

|---|---|---|

| Coercivity & Strength | High coercivity with strong magnetic force, but slightly lower max energy product than Sm2Co17 | Higher magnetic strength and energy product, making it stronger overall |

| Temperature Resistance | Stable up to about 350°C, suitable for high-temp use | Better temperature stability, working well up to 400°C or more without losing magnetism |

| Mechanical Stability | More brittle and prone to chipping, less mechanical robustness | Better toughness and resistance to cracking under mechanical stress |

| Chemical Stability | Strong corrosion resistance but requires coatings for harsh environments | Superior oxidation resistance, ideal for outdoor or harsh chemical settings |

| Cost | Generally cheaper to produce due to simpler composition | More expensive because of complex manufacturing and better properties |

| Size & Shape Options | More limited size and shapes due to brittleness | Offers wider size and shape variability suitable for custom designs |

Impact on Magnet Performance

- SmCo5 is perfect when you need a reliable magnet with strong coercivity in moderate high-temperature settings but can trade off some toughness and top-end strength.

- Sm2Co17 excels in applications demanding extreme temperature stability, higher magnetic strength, and durability, such as aerospace or heavy industrial use.

For specific shape options and sizes, explore our comprehensive guide on the different shape of magnet to see what fits your project best.

Advantages and Disadvantages of SmCo5 and Sm2Co17 Magnets

SmCo5 Magnet Pros and Cons

Pros

- Strong magnetic strength with high coercivity

- Excellent temperature stability up to about 700°F (370°C)

- Great resistance to demagnetization

- Good corrosion resistance without extra coatings

- Consistent performance in harsh environments

Cons

- More brittle compared to some magnets, requiring careful handling

- Limited maximum energy product compared to Sm2Co17

- Smaller size range available due to manufacturing constraints

- Higher cost per strength unit than some alternative magnets

Sm2Co17 Magnet Pros and Cons

Pros

- Higher maximum energy product for stronger magnetic fields

- Better mechanical toughness than SmCo5, less brittle

- Improved resistance to oxidation and corrosion

- Stable at even higher temperatures (up to 750°F / 400°C)

- More flexible manufacturing options, allowing varied shapes and sizes

Cons

- Slightly more complex and costly manufacturing process

- Marginally lower coercivity than SmCo5 in certain conditions

- More sensitive to certain heat treatment variations during production

Choosing Between SmCo5 and Sm2Co17 Magnets

- Pick SmCo5 if you need maximum coercivity, simpler magnet shapes, and strong performance in high-temperature but stable environments like aerospace sensors or precision instruments.

- Go with Sm2Co17 when you require higher magnetic strength, better mechanical toughness, and greater resistance to harsh environments such as automotive components, renewable energy solutions, or defense applications.

In , your choice depends on the balance of magnetic power, mechanical durability, temperature demands, and shape flexibility for your specific project.

Application Scenarios for SmCo5 and Sm2Co17 Magnets

SmCo magnets, especially SmCo5 and Sm2Co17, are trusted in many industries because of their strong magnetic performance and high temperature resistance. Here’s a quick look at where these magnets really shine:

Electronics and Motors

Both SmCo5 and Sm2Co17 are popular in precision electronics and high-performance motors. Their ability to maintain magnetism under heat makes them ideal for small motors in robotics, sensors, and actuators used in the US manufacturing sector. SmCo5’s higher coercivity often suits smaller, more precise components, while Sm2Co17 works well in motors needing extra power and stability.

Aerospace and Defense Industry

In aerospace and defense, reliability is non-negotiable. SmCo magnets are perfect here thanks to their resistance to demagnetization and corrosion. Sm2Co17 is often chosen for applications like satellite components and missile guidance systems because of its superior temperature tolerance and strength, making it a staple for US defense contractors.

Medical Equipment

Medical devices require stable magnetic materials that perform consistently in sensitive environments. SmCo5 magnets often find use in MRI machines and other medical imaging tools due to their stable magnetic field and resistance to temperature changes. Sm2Co17’s robustness is valued in surgical tools and high-precision diagnostic equipment.

Renewable Energy Applications

Wind turbines and solar trackers benefit from SmCo magnets’ ability to withstand extreme weather and heat. Sm2Co17 is commonly used in turbine generators because of its high magnetic strength and stability under varying outdoor temperatures. SmCo5 also plays a role in smaller renewable tech, like solar panel positioning systems.

Automotive Industry

As electric vehicles (EVs) grow in popularity, SmCo magnets become more critical. Sm2Co17 magnets support high-performance motors in EVs, offering power and durability. SmCo5 is often found in sensors and small motor components in traditional and hybrid vehicles where temperature stability and precision matter.

Both SmCo5 and Sm2Co17 meet the demanding needs of American industries, each with strengths that fit specific application requirements. Knowing these scenarios helps you pick the right magnet for your project.

Choosing the Right SmCo Magnets for Your Project

Picking the right SmCo magnet—whether SmCo5 or Sm2Co17—depends mainly on your project’s requirements. Here are the key factors to consider:

- Temperature: Sm2Co17 magnets typically handle higher temperatures better, making them ideal for high-heat environments. SmCo5 still offers good temperature resistance but performs best in moderate heat settings.

- Magnetic Field Strength: If you need stronger magnetic force, Sm2Co17 usually delivers higher magnetic strength, while SmCo5 provides stable magnetism with excellent coercivity.

- Cost: SmCo5 magnets are generally less expensive than Sm2Co17 due to simpler manufacturing, but this varies with size and specifications.

- Physical Environment: Sm2Co17 is more chemically stable and mechanically tougher, great for harsh or abrasive conditions. SmCo5 is reliable in less demanding environments.

- Size and Shape Needs: Some specific shapes or sizes may influence your choice, and NBAEM offers various custom options for different project demands. You can explore magnet shapes and sizes here to find what suits your design best: different shape of magnet.

NBAEM has extensive experience supporting U.S. clients with SmCo magnet solutions tailored to their needs. We provide expert guidance, ensuring you pick the right type for your temperature, strength, and durability needs. Plus, we offer customization to match unique project specs so you get exactly what you need.

Whether it’s for motors, aerospace, or specialized industrial use, NBAEM’s team is ready to help you find the perfect SmCo magnet for your application.

Care and Handling Tips for SmCo Magnets

SmCo magnets(Samarium Cobalt) are strong and durable, but they still need proper care to keep their magnetic power and physical condition. Here’s how to handle and store SmCo magnets safely:

Best Practices to Avoid Magnet Damage

- Handle with care: SmCo magnets are brittle. Avoid dropping or hitting them against hard surfaces to prevent cracks or chipping.

- Keep magnets apart: Strong magnets can snap together quickly, causing injuries or damage. Use spacers or keep a safe distance when storing multiple magnets.

- Use protective gloves: To avoid pinching fingers, wear gloves or use tools when handling larger magnets.

- Avoid machining after magnetization: Cutting or grinding SmCo magnets post-magnetization can cause fractures and reduce magnetic strength.

Storage and Safety Precautions

- Store in a dry place: Moisture can cause surface oxidation even though SmCo magnets resist corrosion better than some magnets. A dry environment extends their life.

- Keep away from extreme heat: SmCo magnets can handle high temperatures, but avoid exposing them continuously above their max rated temperature to prevent loss of magnetism.

- Use proper containers: Store magnets in non-metallic containers or lined boxes to prevent accidental magnet-to-magnet contact.

- Label clearly: Mark magnetic hazard areas to alert people nearby and avoid accidental damage or injuries.

- Keep electronics and magnetic media away: SmCo magnets can erase data on credit cards, computers, and other devices.

By following these simple care and handling tips, you’ll extend the life and performance of your SmCo5 or Sm2Co17 magnets, ensuring they serve your project reliably.

Why Choose NBAEM as Your SmCo Magnets Supplier

When it comes to sourcing SmCo magnets like SmCo5 and Sm2Co17 for your projects, NBAEM stands out in the U.S. market. Here’s why working with NBAEM makes sense for your business:

Product Quality Certifications and R&D Capabilities

- Certified Quality: NBAEM holds key international certifications ensuring consistent, high-grade SmCo magnets.

- Advanced R&D: Continuous investment in research drives innovation, pushing magnet performance and durability, especially for demanding U.S. industries.

- Strict Quality Control: Every batch is tested for magnetic strength, temperature stability, and physical durability to meet your specs.

Customer Testimonials and Case Studies

- Proven Track Record: American clients in aerospace, renewable energy, and automotive sectors report excellent results using NBAEM’s SmCo magnets.

- Real-World Success: Case studies show how NBAEM’s SmCo5 and Sm2Co17 magnets deliver reliability and efficiency under tough conditions.

- Responsive Support: Customers appreciate NBAEM’s quick, knowledgeable service tailored to U.S. market needs.

Commitment to Innovation and Customer Service

- Custom Solutions: NBAEM offers magnet customization to match your exact requirements on size, shape, and magnetic performance.

- Technical Support: U.S.-based clients get expert advice from magnet specialists ready to optimize your application.

- Ongoing Partnership: NBAEM prioritizes long-term relationships, ensuring you have support from prototype to production.

| NBAEM Advantages | What This Means for You |

|---|---|

| Certified quality | Reliable, consistent magnet performance |

| Strong R&D | Cutting-edge materials tailored to your needs |

| Proven client success | Confidence in choosing a trusted supplier |

| Customization options | Magnets fit your exact project specifications |

| Expert customer support | Fast, focused help whenever you need it |

[…] For more details on SmCo magnet types and comparisons, check out our detailed guide on two different SmCo magnets SmCo5 & Sm2Co17. […]