What Are SmCo Magnets

SmCo magnets

Samarium-cobalt (SmCo) magnets are a type of rare-earth permanent magnet known for their exceptional magnetic strength and excellent temperature stability. Made from an alloy of samarium, cobalt, and other elements, these magnets offer high resistance to demagnetization and corrosion, making them ideal for demanding industrial applications.

There are two primary types of SmCo magnets: SmCo 1:5 and SmCo 2:17. The SmCo 1:5 magnets, often referred to as SmCo5, consist of a simpler crystal structure and provide strong magnetic properties with excellent resistance to oxidation. SmCo 2:17 magnets, or Sm2Co17, have a more complex microstructure that delivers even higher magnetic energy and improved temperature resistance.

Key magnetic properties defining SmCo magnet performance include:

- Magnetic strength (Br): The measure of magnetization or magnetic flux density

- Coercivity (Hcj): The resistance to demagnetization

- Maximum energy product (BHmax): Indicates the magnet’s overall energy density and strength

- Temperature stability: Ability to maintain magnetic properties under high heat

Together, these characteristics make SmCo magnets a preferred choice where strong, stable magnets are needed in harsh environments or at elevated temperatures.

Why Do SmCo Magnet Grades Matter

SmCo magnet grades are essentially a way to classify these magnets based on their magnetic strength, coercivity (resistance to demagnetization), and temperature stability. Each grade reflects how strong the magnet is and how well it performs under different conditions, especially heat.

The grade you choose directly affects the magnet’s performance. Higher grades usually offer stronger magnetic force and better resistance to high temperatures, but they also come with a higher price tag. Lower grades might be more cost-effective but can lose strength or become unstable in demanding environments.

Common Grades of SmCo Magnets Explained

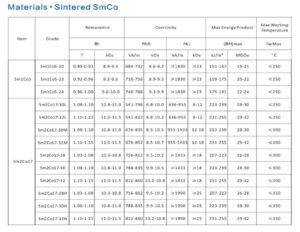

Main SmCo magnets grades

SmCo magnets mainly come in two types: SmCo 1:5 (SmCo5) and SmCo 2:17 (Sm2Co17). Each has specific grades based on their magnetic strengths, coercivity, maximum energy product, and temperature limits.

SmCo 1:5 Magnets (SmCo5)

These are known for their excellent temperature stability and corrosion resistance. Typical grades include:

- Grade 22:

- Br (Residual Induction): ~9.4 kG

- Hcj (Coercivity): ~12 kOe

- (BH)max (Max Energy Product): ~16 MGOe

- Max Operating Temperature: ~250°C

- Grade 24:

- Br: ~9.5 kG

- Hcj: ~13 kOe

- (BH)max: ~18 MGOe

- Max Operating Temperature: ~250°C

- Grade 26:

- Br: ~9.6 kG

- Hcj: ~15 kOe

- (BH)max: ~20 MGOe

- Max Operating Temperature: ~275°C

- Grade 28 and Grade 30 offer slightly higher magnetic strength and coercivity, with max operating temperatures up to 280°C.

SmCo 2:17 Magnets (Sm2Co17)

These have higher magnetic energy and better performance at elevated temperatures but can be less corrosion resistant. Common grades are:

- Grade 28:

- Br: ~10.0 kG

- Hcj: ~18 kOe

- (BH)max: ~26 MGOe

- Max Operating Temperature: 300°C

- Grade 30:

- Br: ~10.2 kG

- Hcj: ~22 kOe

- (BH)max: ~28 MGOe

- Max Operating Temperature: 310°C

- Grade 32:

- Br: ~10.5 kG

- Hcj: ~25 kOe

- (BH)max: ~30 MGOe

- Max Operating Temperature: 320°C

- Grades 34 and 36 push these limits further, with max temperatures reaching 350°C and higher coercivity, suited for demanding industrial uses.

Comparison Table of SmCo Grades

| Grade | Type | Br (kG) | Hcj (kOe) | (BH)max (MGOe) | Max Temp (°C) | Price Index* |

|---|---|---|---|---|---|---|

| 22 | SmCo 1:5 | 9.4 | 12 | 16 | 250 | Low |

| 24 | SmCo 1:5 | 9.5 | 13 | 18 | 250 | Low-Medium |

| 26 | SmCo 1:5 | 9.6 | 15 | 20 | 275 | Medium |

| 28 | SmCo 1:5 | 9.8 | 16 | 21 | 280 | Medium |

| 30 | SmCo 1:5 | 10.0 | 18 | 22 | 280 | Medium-High |

| 28 | SmCo 2:17 | 10.0 | 18 | 26 | 300 | Medium-High |

| 30 | SmCo 2:17 | 10.2 | 22 | 28 | 310 | High |

| 32 | SmCo 2:17 | 10.5 | 25 | 30 | 320 | High |

| 34 | SmCo 2:17 | 10.7 | 28 | 32 | 340 | Very High |

| 36 | SmCo 2:17 | 11.0 | 30 | 34 | 350 | Very High |

*Price index reflects relative cost based on magnetic performance and material composition.

Understanding these grades helps in selecting the right samarium-cobalt magnet for your specific needs, balancing magnetic power, temperature resilience, and cost.

For more details on SmCo magnet types and comparisons, check out our detailed guide on two different SmCo magnets SmCo5 & Sm2Co17.

How to Choose the Right SmCo Magnet Grade

Picking the right SmCo magnet grade depends on a few key factors. Here’s what you need to consider:

Key Factors to Consider

-

Operating Temperature

Choose a grade that can handle the highest temperature your application will face. Some SmCo grades work well above 300°C, while others are better suited for lower temps.

-

Magnetic Field Requirements

Look at the magnetic strength (Br) and coercivity (Hcj) needed. Higher grades offer stronger magnetic performance but often at a higher price.

-

Mechanical Strength and Durability

Consider if your magnet will face physical stress or vibration. Some grades are more brittle or less durable under mechanical load.

-

Environmental Conditions

SmCo magnets resist corrosion, but extremely harsh environments might require specific coatings or grades with better thermal and chemical stability.

Performance vs Cost Trade-Offs

| Grade Type | Magnetic Strength | Max Temperature | Cost Level | Best For |

|---|---|---|---|---|

| SmCo 1:5 | Moderate | Up to 300°C | Lower | General industrial uses |

| SmCo 2:17 | High | Up to 350°C+ | Higher | High-performance & aerospace |

Higher grades give you better magnetic strength and temperature tolerance but will cost more. Balancing performance needs with your budget is key.

Typical Application Scenarios

-

Lower Grade SmCo (22, 24)

Great for sensors, small motors, and devices with moderate heat and stress.

-

Mid-Grade SmCo (26, 28, 30)

Ideal for automotive parts, aerospace components, and medical equipment where reliability and higher temperatures matter.

-

High Grade SmCo (32, 34, 36)

Best for demanding environments like turbines, satellite systems, or high-temp industrial machines.

By matching your application needs with the right grade, you get optimal performance without overspending.

Advantages of Choosing NBAEMs SmCo Magnets

When you choose NBAEMs SmCo magnets, you’re getting products built to high-quality standards. NBAEMs uses strict quality control to ensure every magnet meets precise magnetic strength and stability requirements. This focus on quality means you get reliable, consistent magnets suited for demanding uses.

NBAEMs also offers customized solutions tailored to your project needs. Whether you need specific sizes, grades, or magnetic properties, their team works with you to deliver exactly what fits your application.

Technical support is another strong point. NBAEMs provides expert guidance, helping you pick the right SmCo magnet grade and troubleshoot any performance questions. Their product certifications back up the quality and compliance, giving you extra peace of mind.

With a well-established supply chain and extensive experience in the Chinese market, NBAEMs ensures smooth ordering, timely deliveries, and competitive pricing. This reliability is key for customers in the worldwide looking for consistent and cost-effective SmCo magnets.

FAQs About SmCo Magnet Grades

What determines the grade of SmCo magnets?

The grade mainly depends on the magnet’s magnetic strength (Br), coercivity (resistance to demagnetization, Hcj), and energy product (BHmax). These key properties vary based on the magnet’s composition and manufacturing process, defining how strong and temperature-resistant the magnet is.

Can I mix different grades within one application?

Mixing grades is possible but not always ideal. Different grades have varying magnetic strength and temperature tolerances, which can cause uneven performance or magnet aging over time. It’s best to choose a single grade suited for the application’s operating conditions to ensure stability.

How does temperature affect different grades?

Higher-grade SmCo magnets generally handle elevated temperatures better without losing magnetic power. For example, SmCo 2:17 grades offer higher max operating temperatures than 1:5 types. Using a lower grade beyond its temperature limits can lead to permanent loss of magnetism.

How is the price affected by different grades?

Prices vary with magnetic performance and material complexity. Higher grades with stronger magnetic properties and better temperature resistance cost more due to advanced alloying and processing. Balancing performance needs with budget helps you select the most cost-effective grade for your use.

Leave A Comment