Understanding Magnetization Directions

Magnetization refers to the process of aligning the magnetic domains within a material so that their magnetic moments point in the same direction. In a non-magnetized state, these domains are oriented randomly, canceling each other’s magnetic effects. When magnetized, the domains align, creating a strong, unified magnetic field. This is the fundamental principle behind permanent magnets and their ability to attract certain materials, as explained in more detail in our guide on what is permanent magnetism.

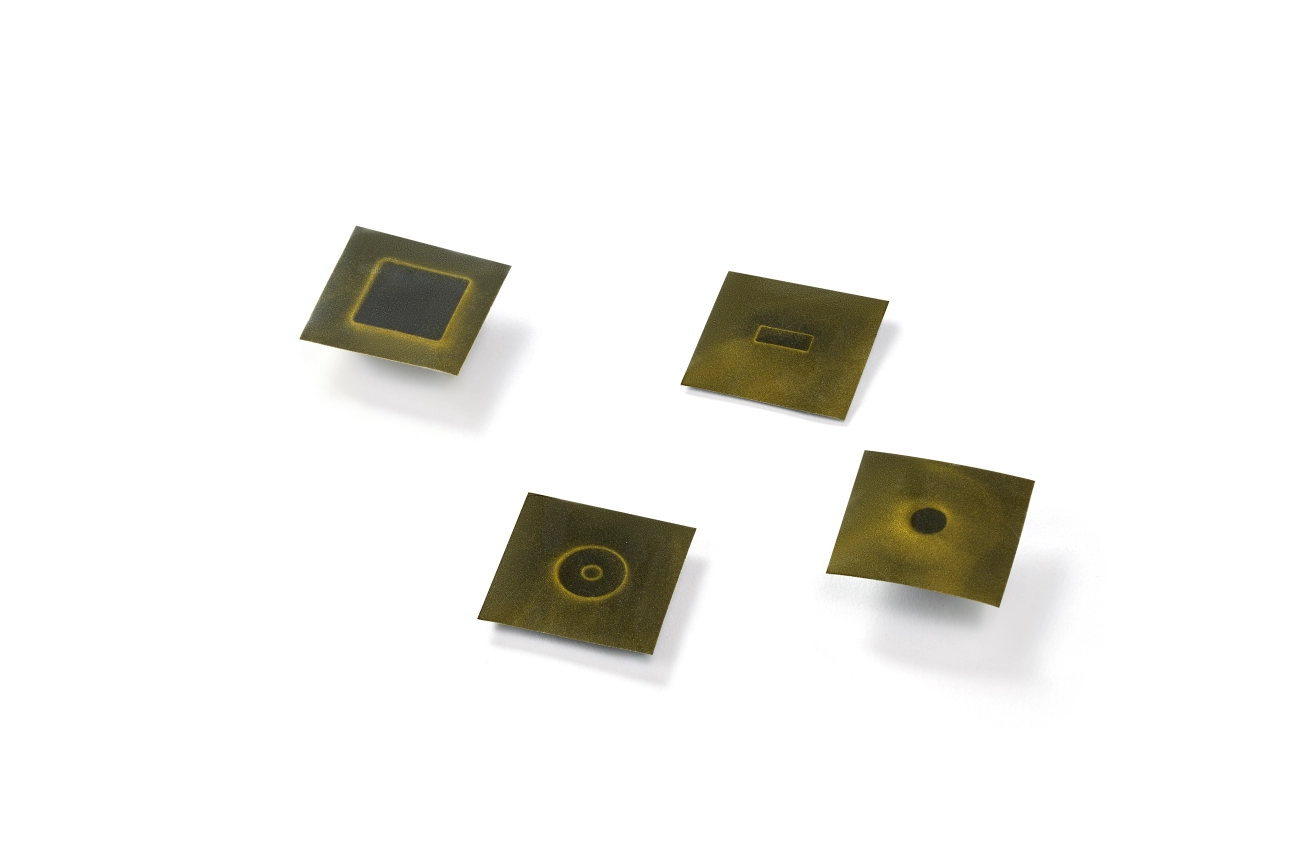

Magnets can be magnetized in different directions depending on their intended use. The three most common magnetization types include:

- Axial Magnetization – The magnetic poles are located on the two flat ends of the magnet, with the magnetic field running along its central or longitudinal axis.

- Diametric Magnetization – The poles are located on opposite curved sides of a cylindrical magnet, so the magnetic field runs across the diameter.

- Radial Magnetization – The magnetic field radiates outward or inward from the center, often used in ring magnets for specific rotating applications.

Understanding these directions is essential because the magnetization type directly affects how the magnet interacts with other magnetic materials, components, and systems. Choosing the right magnetization ensures maximum efficiency in your application.

What Does Axially Magnetized Mean

An axially magnetized magnet is one that’s magnetized along its longitudinal axis — basically, from one flat end of the magnet straight through to the other. In this setup, the north pole is on one flat face, and the south pole is on the opposite flat face.

This type of magnetization is most common in:

- Cylinder magnets (like rods and discs)

- Ring magnets (hole in the middle, poles on flat faces)

Magnetic Field Direction in Axial Magnets

In an axially magnetized magnet, the magnetic field lines run parallel to the axis of the shape — exiting from the north face, looping through the surrounding space, and reentering at the south face. This makes them ideal for applications that require pulling force along the magnet’s length instead of across its side.

The Physics in Simple Terms

When the magnet is made, its magnetic domains — tiny regions inside the material — are aligned so they point in the same direction along the length of the magnet. The stronger and more uniform this alignment, the stronger the magnet’s pull in that axial direction.

How Are Magnets Axially Magnetized

I’ll walk you through how axial magnetization is done, from production to quality checks.

Manufacturing and magnetizing process overview

- Produce the blank magnet (cylindrical, ring, or rod) to final dimensions first.

- Place the part in a magnetizing fixture so the desired long axis lines up with the magnetizing field.

- Apply a strong magnetic field along that longitudinal axis to align the magnetic domains. For strong rare-earth magnets (NdFeB, SmCo) we often use pulsed fields; for ferrites a steady DC field can work.

- For multi-pole or custom patterns, we use specialized fixtures or segmented coils to create the required axial field pattern.

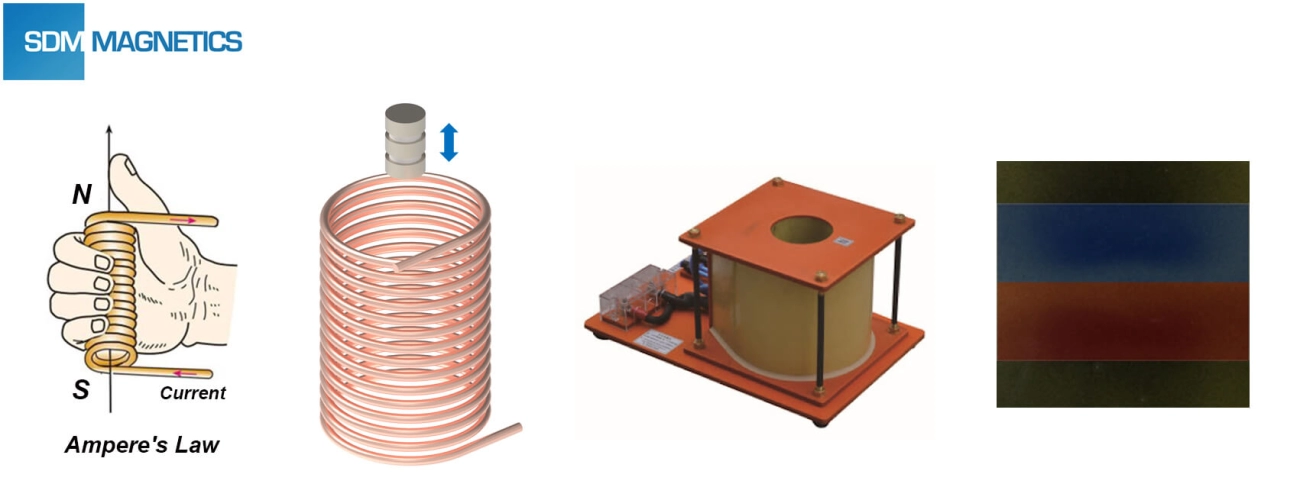

Equipment and techniques used for axial magnetization

- Solenoid coils or long straight coil setups — common for simple axial magnetization where the field runs along the length.

- Pulse magnetizers — used for high-coercivity materials (NdFeB). Provide short, very strong fields to fully saturate the material.

- DC magnetizers with yokes — good for lower-force magnetizing and production runs.

- Custom jigs and fixture blocks — hold rings and odd shapes while keeping the axis aligned.

- Magnetic circuit tooling — helps concentrate the field into the part for consistent results.

- Safety gear and proper shielding are standard because magnetizing pulses and high fields can be hazardous.

Quality control considerations

- Field measurement: Use gaussmeters or fluxmeters to verify surface field strength and direction (axial field peak where expected).

- Sample mapping: Map a representative set of parts for field uniformity and pole placement.

- Material checks: Verify coercivity, remanence, and grade before magnetizing.

- Dimensional and fixture checks: Ensure parts are concentric and seated correctly to avoid misaligned poles.

- Traceability: Keep NIST-traceable calibration records and batch certificates for U.S. customers who need QA documentation.

- Stress testing: Temperature and demagnetization tests as required by the application.

This process keeps axial magnetization consistent and reliable for motors, sensors, and other U.S.-market applications.

Applications of Axially Magnetized Magnets

Axially magnetized magnets are used across many industries because their magnetic field runs straight through the length of the magnet, making them ideal for setups where force or flux needs to be directed along one axis. Here are some of the most common applications in the U.S.:

Motors and Generators

- Used in rotors to create strong, consistent magnetic fields along the shaft.

- Popular in electric vehicles, power tools, and industrial machinery.

Sensors and Actuators

- Provide precise magnetic response in linear or rotational position sensors.

- Common in automotive systems, robotics, and automation equipment.

Magnetic Couplings

- Transfer torque through sealed barriers without physical contact.

- Perfect for pumps and mixers in chemical, medical, and food industries where contamination must be avoided.

Loudspeakers and Audio Equipment

- Deliver accurate magnetic alignment for clean sound reproduction.

- Found in home audio systems, studio monitors, and portable speakers.

Medical Devices

- Used in MRI components, surgical tools, and diagnostic equipment.

- Axial magnetization offers predictable field placement for sensitive instruments.

Advantages over other magnetization types:

- Stronger pull along the magnet’s central axis.

- Easier alignment in cylindrical and ring-shaped designs.

- More efficient for applications where the magnetic field must pass directly through the magnet’s length.

Axially Magnetized vs Other Magnetization Types

Axial magnetization isn’t the only way magnets can be magnetized. It’s one of the most common, but diametric and radial types are also widely used. Understanding the difference helps you pick the right one for your design.

Main differences in magnetization direction

| Magnetization Type | Magnetic Poles Location | Field Direction | Common Shapes | Typical Uses |

|---|---|---|---|---|

| Axial | At each flat face | Along the length (end to end) | Cylinders, discs, rings | Motors, sensors, couplings |

| Diametric | On curved sides | Across the diameter | Discs, cylinders | Magnetic stirrers, specialized couplings |

| Radial | Around circumference | From center outward | Rings | Encoders, alternators |

Benefits of Axial Magnetization

- Strong end-to-end field – Ideal for applications needing a focused pull on flat surfaces.

- Easy to manufacture – Fits well with standard production processes.

- Reliable for moving parts – Works great in rotating machinery where poles align with rotation axis.

Limitations of Axial Magnetization

- Less effective for applications needing a side pull or uniform all-around field.

- Field pattern can be too narrow for certain sensing systems.

Choosing the Right Magnetization

When deciding between axial, diametric, or radial:

- Look at the pull direction you need – End-to-end? Go axial. Side force? Diametric may work better.

- Match to the mating surface – Flat contact favors axial magnets.

- Factor in your assembly – For example, if you’re designing a ring that needs even magnetic distribution, radial is the way to go.

- Consider performance balance – Axial often gives the best balance between power, cost, and availability.

Selecting Axially Magnetized Magnets from NBAEM

If you’re looking for axially magnetized magnets, NBAEM offers a wide range of options to fit different applications here in the U.S. and worldwide. We supply magnets in NdFeB (neodymium), SmCo (samarium cobalt), and ferrite/ceramic materials, all available with precise axial magnetization. Whether you need a small, high-strength piece for a sensor or a robust industrial-grade magnet for a motor, we can match the size, coating, and performance specs you need.

Magnet Types Available with Axial Magnetization

- NdFeB (Neodymium Iron Boron) – strongest magnetic performance, ideal for compact designs

- SmCo (Samarium Cobalt) – high-temperature stability, corrosion resistant

- Ferrite/Ceramic – cost-effective for large-volume and outdoor use

- AlNiCo – excellent temperature stability, lower coercivity for specialized applications

Custom Magnetization Services

We can produce custom sizes, shapes, and magnetization strengths to suit your project. That includes specialty grades for high-temp, marine, or medical environments.

How NBAEM Ensures Quality

- Strict QC checks from raw material to finished product

- Magnetization accuracy testing to ensure proper axial alignment

- Surface and coating inspections for durability and protection

Global Shipping and Support

NBAEM supplies U.S. companies with fast, reliable delivery from our production facilities. We hold ISO-certified quality systems and can provide full compliance documentation for regulated industries. Our support team works directly with engineers and purchasing managers to make sure you get the right magnet—on time and to spec.

FAQs About Axially Magnetized Magnets

Here are some quick answers to common questions about axially magnetized magnets, plus a few tips for avoiding problems.

What does axially magnetized mean

It means the magnet’s north and south poles are located on the flat faces at each end of its length. The magnetic field runs straight through from one end to the other. This is common in disc, cylinder, and ring-shaped magnets.

What’s the difference between axial, diametric, and radial magnetization

- Axial – Poles on the ends (lengthwise)

- Diametric – Poles on the curved sides (across the diameter)

- Radial – Poles arranged around the circumference, pointing outwards or inwards

Can I cut or drill an axially magnetized magnet

No. Cutting or drilling will typically damage the material, reduce strength, and change the magnetic pattern. Order the size and shape you need from the start.

How should I store axially magnetized magnets

- Keep them away from strong opposing magnetic fields

- Use spacers or keepers between magnets to prevent demagnetization

- Store in a dry place to avoid corrosion (especially for NdFeB magnets)

How do I tell which way my magnet is magnetized

A simple way is to use a known north or south pole of another magnet and see which face attracts or repels. Pole finders and gauss meters give more precise readings.

Troubleshooting and best practices

- Weak pull? Check if your magnet is too far from the target surface or if there’s a non-magnetic gap in between.

- Magnets sticking together too strongly? Use plastic or cardboard spacers during handling.

- Loss of magnetism? Avoid high heat, strong opposing magnets, or heavy mechanical shock.

Leave A Comment