Have you ever wondered what factors affect the properties of magnet—and why some magnets suddenly fail in critical applications? Whether you’re an engineer, R&D specialist, or technical buyer, understanding these underlying technical drivers is crucial. From material composition and microstructure to temperature effects and corrosion resistance, each factor shapes the magnet’s strength, stability, and lifespan. Getting this right can mean the difference between reliable performance and costly downtime—especially for high-demand magnets like NdFeB, SmCo, AlNiCo, or ferrite types. In this guide, we’ll break down the 8 key elements that control properties of magnet and help you make smarter, data-driven choices for design, sourcing, and long-term success. Let’s get straight to the heart of what truly matters when selecting or engineering permanent magnets in 2025.

Material Composition and Alloy Ratio

The properties of magnets heavily depend on their material composition and alloy ratio. Different types of magnets—rare-earth, ferrite, AlNiCo, and SmCo—offer distinct performance characteristics, making material choice critical.

Rare-earth magnets, especially Neodymium-Iron-Boron (NdFeB), dominate high-performance applications due to their superior magnetic strength. Key alloy elements in NdFeB include:

- Neodymium (Nd): Boosts remanence (Br) for stronger magnetic fields.

- Dysprosium (Dy) and Terbium (Tb): Added in small amounts to increase coercivity (Hc), enabling magnets to resist demagnetization at higher temperatures.

- Cobalt (Co): Improves thermal stability and corrosion resistance.

- Boron (B): Stabilises the crystal structure, enhancing magnetic hardness.

The addition of heavy rare-earth elements like Dy and Tb is vital for applications requiring high coercivity, particularly in motors and wind turbines operating under thermal stress.

Ferrite magnets offer good corrosion resistance at a low cost but have lower energy products compared to rare-earth magnets. Meanwhile, AlNiCo magnets excel in thermal stability but lag in coercivity.

Material purity and oxygen control during manufacturing are crucial. Oxygen contamination weakens NdFeB magnets, reducing both remanence (Br) and coercivity (Hc). High-purity rare-earth metals and strict oxygen management ensure consistent magnetic performance.

| Magnet Type | Key Alloy Elements | Primary Features | Typical Applications |

|---|---|---|---|

| NdFeB | Nd, Fe, B, Dy, Tb, Co | High Br and Hc, variable thermal | Motors, sensors, electronics |

| SmCo | Sm, Co | Excellent thermal stability, corrosion resistance | Aerospace, military |

| AlNiCo | Al, Ni, Co | High temperature tolerance | Instruments, loudspeakers |

| Ferrite | Fe, Ba or Sr oxides | Low cost, corrosion resistant | Household appliances, speakers |

Understanding the precise alloy ratio helps you select the right magnet grade tailored to your application’s magnetic strength, thermal environment, and durability requirements.

Microstructure and Grain Size

The microstructure and grain size of a magnet play a crucial role in determining its magnetic properties. In sintered magnets, grain alignment is essential—well-aligned grains improve remanence (Br) by allowing magnetic domains to line up more effectively, which boosts overall magnet strength.

Another factor is grain boundary phase engineering. The composition and thickness of grain boundary phases can either enhance coercivity (Hc) by pinning domain walls or weaken performance if not optimized. For example, carefully controlled grain boundaries in NdFeB magnets improve resistance to demagnetization.

When comparing nano-crystalline and conventional microstructures, nano-crystalline magnets often offer higher coercivity and better temperature stability due to their fine grains and uniform structure. However, conventional microstructures are sometimes preferred for easier manufacturing or cost reasons.

The manufacturing steps like jet-milling and pressing directly impact microstructure. Jet-milling reduces particle size, promoting better grain uniformity, while pressing (axial, isostatic, or transverse) influences grain alignment and density. Together, these processes can fine-tune magnet performance by enhancing magnetic uniformity and mechanical strength.

For applications demanding high-performance magnets, understanding and controlling microstructure is key. If you’re working with magnets in demanding environments, consider how these factors affect the final properties of magnets and check out more about magnets used in renewable energy for insights into advanced microstructural requirements.

Manufacturing Process

The manufacturing process plays a huge role in determining the final properties of a magnet. A key distinction is between sintered and bonded magnets. Sintered magnets generally offer higher magnetic performance because their grains are densely packed and well-aligned, which boosts remanence (Br) and coercivity (Hc). Bonded magnets, on the other hand, are made by mixing magnetic powder with a polymer binder. They’re easier to shape and cheaper but usually have lower maximum energy product (BHmax).

One of the critical steps in making sintered magnets, especially NdFeB types, is hydrogen decrepitation. This process breaks down large alloy chunks into fine powders by absorbing hydrogen, which makes milling easier and improves magnetic uniformity. After that, jet milling refines the powder further, controlling particle size to optimize the microstructure and magnetic properties.

Sintering temperature and time also affect the microstructure. Too high or uneven sintering can lead to grain growth or defects, reducing performance. Choosing the right pressing method is crucial to align grains properly:

- Axial pressing aligns grains along one axis, improving magnetic directionality.

- Isostatic pressing compresses equally in all directions, offering uniform density.

- Transverse pressing presses perpendicular to the preferred magnetic axis, which is less common but useful for specific shapes.

After pressing and sintering, heat treatment and tempering steps help relieve internal stresses and improve coercivity and mechanical strength. These stages fine-tune the distribution of elements at grain boundaries, which impacts how well the magnet resists demagnetization.

For those interested in the practical impact of these manufacturing choices, understanding how these factors tie into devices like generators is important. Exploring the detailed workings of a magnetic generator can give you a clearer picture of why magnet quality matters in real-world applications.

Temperature and Thermal Stability of Magnets

Temperature plays a big role in how magnets perform over time. Each magnetic material has a Curie temperature—the point where it loses its magnetism completely. For example, NdFeB magnets usually have a Curie temperature around 310-400°C, while SmCo magnets can handle up to 700°C. Knowing this helps us avoid pushing magnets past their limits.

Magnets also experience reversible and irreversible losses when heated. Reversible loss means the magnet’s strength drops as temperature rises but recovers once cooled. Irreversible loss happens when the magnet overheats past a critical point, causing permanent damage to its magnetic properties.

The maximum operating temperature (MOT) varies by magnet grade. Grades like N (normal) and M (medium) work well up to about 80-100°C, while H (high), SH (super high), UH (ultra high), and EH (extreme high) grades can safely operate at increasingly higher temperatures—sometimes up to 200°C or more. This grading system helps you pick a magnet that fits your device’s temperature conditions without risking demagnetization.

Two important temperature-related factors are the thermal coefficients of remanence (Br) and coercivity (Hc). Br usually decreases by about 0.1% per °C, meaning the magnet’s leftover magnetism weakens as it gets hotter. Hc drops even faster, which impacts the magnet’s resistance to external magnetic fields and demagnetization. Materials designed for high temperatures often have specially engineered compositions to minimize these losses.

Choosing the right grade based on expected operating temperatures is essential for long-term stability and performance. For a deeper dive into magnet performance and energy generation, check out this resource on generating energy from magnets.

External Magnetic Field & Demagnetization Risk

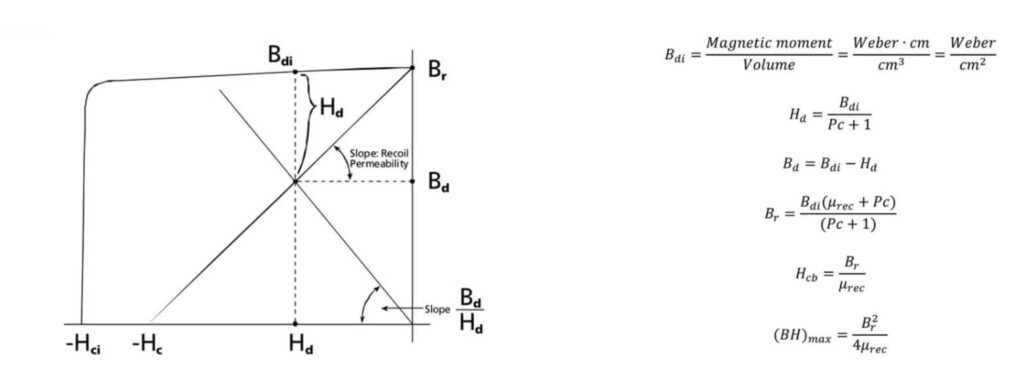

One major factor influencing magnet performance is exposure to external magnetic fields, which can cause partial or complete demagnetization. The demagnetization curve illustrates how a magnet’s magnetic field weakens when an opposing magnetic field is applied. The critical knee point on this curve marks where irreversible loss of magnetism begins, making it essential to operate magnets within safe limits.

In practical applications like electric motors, armature reaction creates a counter magnetic field that can push the magnet towards this knee point. This risk increases with load and current, so designing magnets with a sufficient intrinsic coercivity (Hci) margin is critical to resist these opposing fields effectively.

How to Choose the Proper Hci Margin

- Understand operating conditions: Higher temperatures and stronger opposing fields require magnets with greater Hci.

- Select magnet grades accordingly: Grades with higher coercivity (e.g., H, SH, UH) offer better demagnetization resistance but often at a higher cost.

- Consider safety factors: A 20-30% margin above the maximum expected demagnetizing field is a common engineering practice.

- Design for application: Motors and generators especially need magnets with Hci well above the working field to avoid efficiency loss and damage.

Balancing the magnet grade and coercivity ensures long-lasting performance without risking irreversible demagnetization. For applications sensitive to external magnetic fields, having a clear understanding of the demagnetization curve and Hci margin helps optimize both durability and efficiency.

Surface Coating and Corrosion Protection

Surface coating plays a crucial role in protecting magnets from corrosion, especially for sensitive materials like NdFeB that are prone to rust and degradation. Common coatings include NiCuNi (nickel-copper-nickel), zinc (Zn), epoxy, and specialized coatings like Everlube or combined treatments such as passivation followed by epoxy.

- NiCuNi coating offers excellent corrosion resistance and good wear protection, making it a popular choice for neodymium magnets.

- Zinc coatings provide moderate protection, often used as a cost-effective option but less durable than nickel-based coatings.

- Epoxy coatings are ideal for harsh environments, including exposure to moisture and chemicals. They form a solid barrier but may wear more easily in mechanical applications.

- Advanced treatments like passivation plus epoxy combine the best of both worlds, ensuring chemical stability and physical protection.

In corrosion testing, such as the salt spray test, magnets with NiCuNi coatings generally show superior resistance, maintaining magnetic properties longer under aggressive conditions. Meanwhile, epoxy coatings can withstand longer exposure times but require uniform application to avoid weak spots.

Coating thickness and the presence of pinholes or microscopic defects are critical factors. Thinner coatings or pinholes allow moisture to seep in, leading to localized corrosion that can degrade magnetic performance. Ensuring an even, defect-free layer is vital to maintaining long-term stability.

For applications with high humidity or corrosive atmospheres, choosing the right coating and quality control during manufacturing are key to preserving magnet strength and durability. If you want to explore how different shapes and finishes impact magnet protection, check out our guide on rectangular neodymium magnets for more insights.

Mechanical Properties and Brittleness

Magnets, especially rare-earth types like NdFeB, are known for their brittleness, which significantly impacts their mechanical properties and handling during machining. Understanding the difference between compressive and tensile strength is key here: magnets typically show much higher compressive strength but are weak under tensile stress. This means they can withstand pressure fairly well but are prone to cracking or chipping when stretched or bent.

When machining magnets through cutting, grinding, or wire-EDM, brittleness poses a real challenge. Improper handling or tooling can cause fractures, micro-cracks, or surface chips, which degrade the magnet’s performance and durability. Using gentle, controlled machining processes and sharp tools helps reduce mechanical stress on the magnet during shaping or sizing.

During assembly, even slight impacts or undue stress raise the risk of cracking. It’s crucial to handle magnets carefully and avoid sudden shocks or bending forces. Proper fixturing and cushioning during mounting can prevent damage that isn’t always visible but can affect magnetic properties long term.

In short, the inherent brittleness of magnets demands attention to mechanical strength and cautious machining methods to maintain their performance and structural integrity. This is especially true for high-performance magnets where even minor surface damage can lead to magnetic loss or early failure.

Aging and Long-Term Stability

Permanent magnets aren’t just tested when new—they change over time due to magnetic aging. This natural phenomenon causes a slow decline in key properties like remanence (Br) and coercivity (Hc), mainly from internal structural relaxation. After years of use, tiny shifts in the microstructure reduce magnetic performance, especially if exposed to fluctuating temperatures or stress.

Structural relaxation means the magnet’s grains settle into a more stable but less magnetically active arrangement. This effect is gradual but can lead to noticeable losses in strength if the magnet isn’t designed for long-term stability.

To ensure reliability, industry standards like IEC 60404-8-1 specify tests for magnetic aging. These involve accelerated aging cycles, typically at elevated temperatures and humidity, to predict how magnets behave over time in real environments. Selecting magnets certified under such standards helps avoid unexpected failures in applications like motors, sensors, or medical devices.

Understanding this aging process is key to choosing the right magnet grade, ensuring your device maintains optimal performance for years. For deeper insights on measuring magnet strength and factors affecting magnet durability, resources like how to measure magnet strength can be very helpful.

How to Choose the Right Magnet Grade for Your Application

Choosing the right magnet grade depends on where and how you plan to use it. Different applications demand specific magnetic properties, temperature resistance, and cost considerations. To make the best choice, match the magnet’s performance profile with your device’s requirements.

Application Matrix

| Application | Recommended Magnet Grade | Key Requirements |

|---|---|---|

| Motors (automotive, industrial) | N35 to N52 NdFeB (N to EH grades) | High energy product (BHmax), good thermal stability, strong coercivity (Hci) |

| Sensors & small devices | N35 to N45 NdFeB, bonded magnets | Moderate strength, compact size, cost-effective |

| Wind turbines | SmCo, high-grade NdFeB (H to EH) | Excellent thermal and corrosion stability, high coercivity |

| MRI machines | SmCo and AlNiCo | Stable magnetic field, high temperature resistance, low aging |

| Consumer electronics | N35 to N42 NdFeB | Balanced performance and cost, small form factor |

Cost-Performance Trade-off (2025 Pricing Trend)

| Magnet Grade | Typical Price Range (USD/kg) | Performance Highlights | Best Use Cases |

|---|---|---|---|

| N35 – N42 NdFeB | $40 – $60 | Good energy, basic thermal resistance | Consumer electronics, sensors |

| N45 – N52 NdFeB | $60 – $85 | Higher energy, improved coercivity | Motors, actuators |

| SmCo (e.g., SmCo 2:17) | $150 – $220 | High temperature stability, corrosion-resistant | Aerospace, wind turbines |

| AlNiCo | $30 – $45 | Stable at high temp, lower BHmax | Measurement devices, sensors |

| Bonded NdFeB | $35 – $50 | Lower strength, flexible shapes | Miniature applications |

Tips for Selecting the Right Magnet Grade

- Consider the operating temperature: Higher grades like H, SH, UH, and EH handle higher temperatures with less irreversible loss.

- Factor in demagnetization risk: Use grades with higher coercivity (Hci) for high-demag environments.

- Match mechanical requirements: If assembly involves machining or impact, choose grades with better mechanical toughness.

- Budget accordingly: Don’t overspend on super-high grades if your application doesn’t require it.

By evaluating these factors along with the application matrix, you can confidently pick a magnet grade that offers the right balance of magnetic properties, durability, and cost. For a deeper dive into magnetic materials and their grades, check out detailed resources on magnetic technologies.

Common Mistakes That Destroy Magnet Performance

Many factors can unintentionally damage magnets and reduce their effectiveness. Here are some common mistakes to watch out for:

- Over-temperature Operation: Exceeding the maximum operating temperature (MOT) can cause irreversible loss of magnetism, especially in NdFeB magnets. Running magnets above their thermal limits leads to permanent drops in remanence (Br) and coercivity (Hc). Always check the magnet’s temperature rating and consider the Curie temperature to avoid performance degradation. For detailed info on temperature effects, see our guide on maximum operating temperature vs Curie temperature.

- Wrong Coating for Humid Environment: Using inadequate surface coating in corrosive or humid conditions invites rust and pitting. Coatings like NiCuNi or Zn offer good corrosion resistance, but thinner or poor-quality coatings with pinholes leave the magnet vulnerable. Epoxy and passivation layers also help but must be carefully applied. Choosing the right coating ensures long-term magnet durability.

- Insufficient Hci in High-Demagnetization Applications: Permanent magnets must have a proper intrinsic coercivity (Hci) margin to withstand demagnetizing fields in motors and actuators. Undersized Hci leads to quick demagnetization and failure. Always select a magnet grade that matches the magnetic load, with margin against the knee point on the demagnetization curve. Understanding this is crucial for reliable magnet performance in demanding applications.

Avoiding these mistakes helps you maintain the magnet’s magnetic properties and mechanical strength, ensuring longer life and stable operation in your projects or products.

Leave A Comment