Are you curious about what a ferrite ring magnet is used for and why it keeps popping up in so many projects? Whether you’re tackling audio issues, building motors, or battling electronic noise, this humble yet powerful magnet often holds the key. In this post, you’ll discover practical uses for ferrite ring magnets—from improving speaker clarity to cutting down EMI interference—and why they’re a go-to choice for engineers and hobbyists alike. Ready to unlock the potential of these cost-effective, corrosion-resistant magnets? Let’s get started!

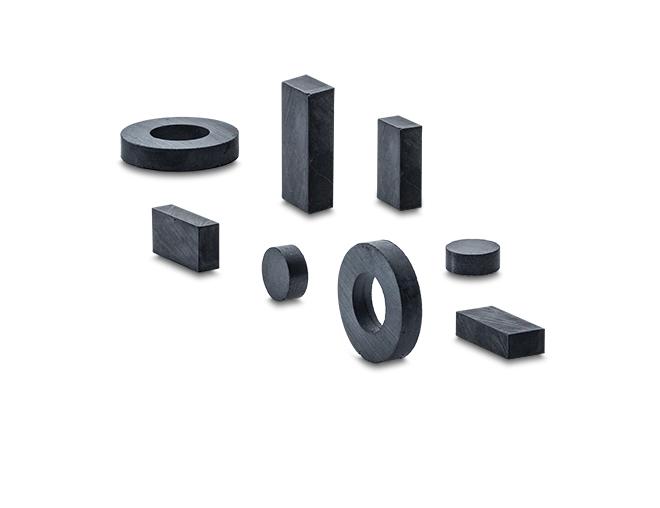

ferrite ring magnet

What Makes Ferrite Ring Magnets Unique

Ferrite ring magnets stand out due to their distinctive composition and magnetic properties. Made primarily from iron oxide mixed with strontium or barium carbonate, these magnets fall under the category of ceramic magnets. This composition gives them a hard, brittle structure while keeping manufacturing costs low.

Key Properties and Specifications

- Magnetic Strength: Moderate compared to rare-earth magnets, usually with a maximum energy product around 3.5 MGOe.

- Corrosion Resistance: Naturally resistant to rust and oxidation, making them ideal for harsh environments.

- Temperature Stability: Can operate reliably up to about 250°C without significant demagnetization.

- Shape and Magnetization: Typically made in a ring or toroidal shape with axial or radial magnetization for specialized applications.

Pros and Cons

Pros

- Affordable alternative to neodymium magnets, offering good value for everyday and industrial uses.

- Excellent corrosion resistance means no need for additional coatings.

- Stable magnetic performance over a wide temperature range.

- Easily shaped into ring forms ideal for coils and inductors.

Cons

- Lower magnetic strength limits use in high-performance motors or compact electronic devices.

- Brittle nature makes them prone to cracking or chipping if mishandled.

- Less efficient in miniaturized applications where strong magnetic fields are needed.

Their balance of cost-effectiveness, durability, and corrosion resistance makes ferrite ring magnets a go-to choice for many industrial and consumer applications where moderate magnetic power is sufficient. For a deeper understanding of permanent magnet types including ferrite, check out our overview for types of magnets.

Core Applications Where Ferrite Ring Magnets Shine in Everyday and Industrial Use

Ferrite ring magnets are super versatile and show up in a ton of places, both at home and in industry. Here’s a quick look at where they really stand out:

Audio and Acoustics

These magnets are often used as speaker magnet cores in everything from home audio systems to car speakers. Their stable magnetic performance and affordable cost make them perfect for delivering clear sound without breaking the bank.

Motors and Generators

Ferrite ring magnets are common in permanent magnet motors and small generators because they handle heat well and resist corrosion. They provide consistent magnetic force, which helps keep motors running smoothly and efficiently over time.

Holding and Clamping Systems

In industrial settings, these are go-to magnets for holding and clamping tasks. Because they’re corrosion-resistant and durable, they work reliably in tools, fixtures, and machinery where a strong, stable hold is needed.

Electromagnetic Interference Suppression

If you’ve ever dealt with EMI issues, you might have encountered noise filtering ferrite components or EMI suppression chokes. Ferrite ring magnets help reduce unwanted electronic noise in cables and circuits, improving overall device performance.

Sensors and Specialized Technology

Ferrite rings are used in sensors and specialized equipment thanks to their predictable magnetic fields and durability. This includes everything from magnetic pickups to certain medical devices.

Case Study

Take a U.S.-based manufacturer who switched to ferrite ring magnets in their motor line. They saw a boost in motor lifespan and cut down on costs compared to pricier rare-earth magnets, proving ferrite is a smart choice when performance meets budget constraints.

In short, ferrite ring magnets balance cost, durability, and performance, making them a solid pick across many everyday and industrial uses right here in the U.S.

How to Select and Implement Ferrite Ring Magnets for Optimal Performance

Choosing the right ferrite ring magnet starts with sizing. Pick a size that fits your device or application without forcing it. Pay attention to the ring’s inner diameter, outer diameter, and thickness—they all affect magnetic strength and fit. Oversized magnets can cause installation headaches or reduce efficiency.

Here are some quick installation tips to make the most of your ferrite ring magnets:

- Align magnetization direction correctly: Most ferrite ring magnets use axial magnetization, so match your setup with this to avoid weak performance.

- Avoid dropping or impacting: Ferrite magnets are ceramic and brittle; rough handling can cause cracks.

- Use proper mounting: Secure the magnet without over-tightening to prevent damage.

- Keep away from metal debris: Dust or shavings can interfere with magnetic function.

Be mindful of common pitfalls such as:

- Selecting a magnet with too low a grade, resulting in weak magnetic force.

- Neglecting environmental factors like moisture, though ferrite magnets are generally corrosion-resistant.

- Ignoring the need for EMI suppression if your application involves noise-sensitive equipment.

Here’s a simple comparison table to guide your choice:

| Feature | Ferrite Ring Magnets | Alternatives (e.g., Neodymium) |

|---|---|---|

| Magnetic Strength | Moderate | Higher |

| Cost | Budget-friendly | More expensive |

| Corrosion Resistance | Excellent | Often requires coatings |

| Temperature Resistance | Good | Varies, typically lower |

| Brittleness | High | Less brittle |

For detailed magnet grades and strength info, check out magnet grades and pull force. Proper selection and installation help you get reliable, efficient performance in your electric motors, speaker systems, or EMI suppression devices.

Sourcing Quality Ferrite Ring Magnets Why Choose NBAEM

When it comes to buying ferrite ring magnets, quality matters a lot—especially for US customers who expect reliable performance and consistency. NBAEM stands out as a trusted supplier because they offer top-notch ceramic ring magnets made with precision and strict quality control. Their magnets have consistent magnetic strength and corrosion resistance, making them perfect for industrial holding magnets, speaker magnet cores, and EMI suppression chokes.

Here’s why NBAEM is a smart choice:

- High-quality materials: NBAEM uses premium ferrite compositions that deliver strong, stable magnetic properties.

- Wide selection: From budget ferrite alternatives to custom axial magnetization rings, they cover many applications.

- Reliable supply chain: Fast shipping and clear communication help US businesses keep projects on schedule.

- Competitive pricing: For industries looking to manage costs without compromising on performance, NBAEM offers great value.

- Technical support: Their team assists with sizing, installation advice, and choosing the right magnet for your need.

Choosing NBAEM means you’re getting ferrite ring magnets that perform consistently, meet US industrial standards, and come from a supplier who understands the needs of diverse ferrite magnet applications.

FAQs Answering Your Top Questions on Ferrite Ring Magnets

What is a ferrite ring magnet used for?

Ferrite ring magnets are mainly used for motors, speakers, EMI suppression, and holding or clamping. Their ring shape makes them perfect for applications needing magnetic flux to flow through a hollow center.

Are ferrite ring magnets corrosion-resistant?

Yes, ferrite magnets, also called ceramic magnets, naturally resist corrosion, making them great for everyday and industrial environments without extra coatings.

Can ferrite ring magnets replace rare earth magnets?

They can in many cases where cost is a concern and extreme strength isn’t necessary. Ferrite magnets are budget-friendly alternatives but usually have lower magnetic strength than neodymium magnets.

How do I pick the right size ferrite ring magnet?

Look at your device’s design specs, considering inner and outer diameter, thickness, and magnetic pull force. The right size balances magnetic strength and fits your mechanical setup.

Are ferrite ring magnets good for EMI suppression?

Absolutely. They’re often used as noise filtering ferrite cores in cables and electronic components to block unwanted electromagnetic interference.

Can I use ferrite ring magnets in permanent magnet motors?

Yes. They’re popular in permanent magnet motors because of their ease of manufacturing, temperature stability, and cost-effectiveness.

Where can I buy quality ferrite ring magnets in the US?

Look for reputable suppliers like NBAEM that specialize in industrial-grade ferrite magnets with strict quality control and fast U.S. shipping.

If you have more questions or want help choosing the right ferrite ring magnet, feel free to reach out!

Leave A Comment