Imagine tiny metal shavings silently wearing down your engine or gearbox—what if you could stop them before they cause real damage? That’s where a magnetic plug steps in. This simple yet smart device uses a powerful magnet to capture ferrous debris in oil and fluids, protecting your machinery from costly breakdowns. Whether you’re a mechanic, fleet manager, or DIY enthusiast, understanding how a magnetic plug works can save you time, money, and headaches. Ready to discover why these unsung heroes are essential for smarter machinery maintenance? Let’s dive in!

What Exactly Is a Magnetic Plug

Magnetic plug

Ever wonder how to keep your engine or machinery free from harmful metal debris? A magnetic plug is designed to do just that. At its core, a magnetic plug is a specialized component that uses powerful magnets, often neodymium magnets, to attract and hold tiny metal particles circulating in fluids like oil or hydraulic liquid. This helps prevent engine wear and damage by trapping ferrous particles before they cause problems.

There are several types of magnetic plugs depending on the application:

- Magnetic drain plugs replace standard drain plugs in oil sumps, catching metal shavings during oil changes.

- Transmission fill plugs with magnets trap debris in transmission fluid.

- Gearbox vent plugs prevent metal contamination while allowing ventilation.

- Industrial magnetic filters serve larger hydraulic systems to maintain cleanliness.

Each type is designed to fit specific maintenance needs, making magnetic plugs an essential tool for condition-based monitoring and prolonging equipment life.

How Does a Magnetic Plug Work Mechanism and Installation Steps

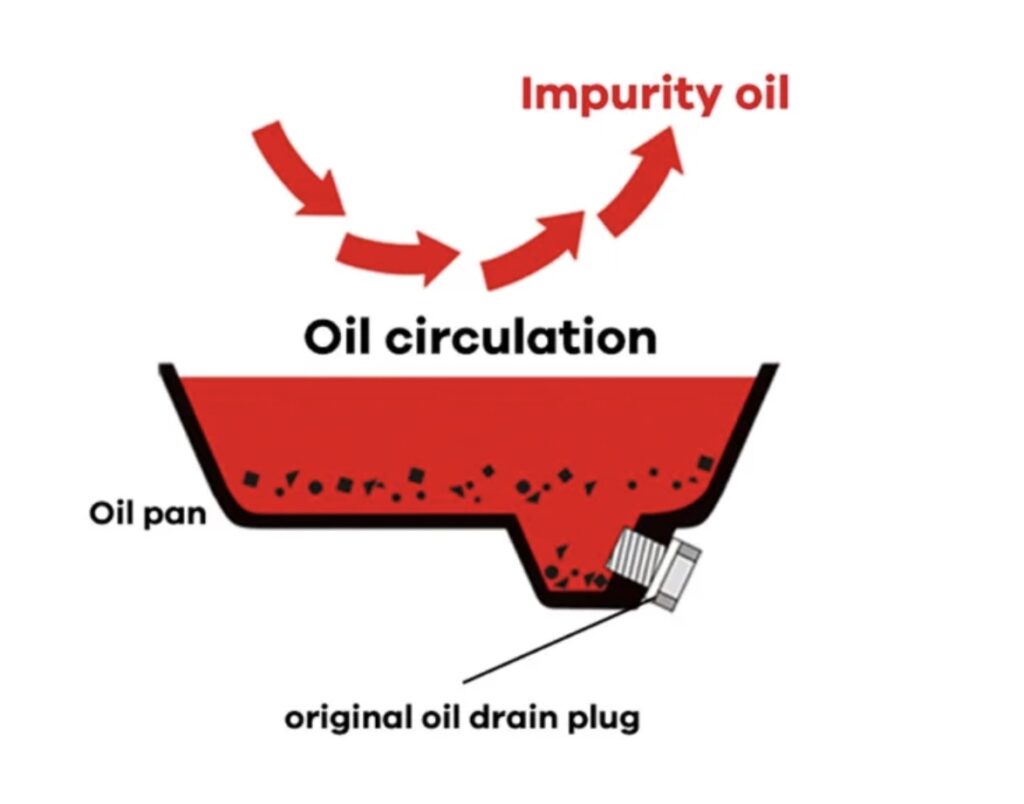

A magnetic plug works by capturing tiny metal particles, like iron or steel debris, that circulate in your engine oil, transmission fluid, or hydraulic systems. Most magnetic plugs use strong neodymium magnets to attract and hold these ferrous particles before they can cause damage or increase engine wear. This prevents buildup and protects parts like the oil sump, gearbox, or transmission from premature wear.

Here’s how it works in a nutshell:

- Magnet attracts metal particles: The neodymium magnet embedded in the plug pulls in any ferrous debris floating in the fluid.

- Traps debris: These particles stick to the magnetic surface, stopping them from circulating and causing damage.

- Easy cleaning: When you check or change fluids, you remove the plug and wipe off the trapped metal.

Installing a magnetic plug is straightforward:

- Locate the correct plug spot: It typically replaces standard drain plugs in oil sumps, gearboxes, or transmission fill points.

- Remove the existing plug: Using the right tools, carefully take out the old plug without spilling fluid.

- Insert the magnetic plug: Screw in the magnetic drain plug by hand to avoid cross-threading, then tighten securely with a wrench—don’t over-tighten.

- Check for leaks: After installation, run the engine or system and inspect for leaks to ensure a proper seal.

Using a magnetic plug adds an easy layer of protection by filtering out harmful metal debris, extending the life of your equipment and reducing maintenance needs.

Key Benefits of Using Magnetic Plugs in Your Systems

magnetic plug system

Using a magnetic plug, like a magnetic drain plug or a neodymium magnet plug, brings real advantages for keeping your engines, gearboxes, and hydraulic systems running clean and smooth. Here’s why they make a difference:

- Engine Wear Prevention: Magnetic plugs attract and hold onto tiny metal shavings and ferrous particles before they can cause serious damage. This helps extend the life of your engine and transmission parts by reducing wear.

- Improved Oil and Fluid Cleanliness: Acting like an oil sump debris trap or a ferrous particle filter, these plugs keep contaminants from circulating through your system. Cleaner oil means better performance and less downtime.

- Easy Installation and Maintenance: Magnetic plugs fit right in place of standard drain or fill plugs. Checking them during routine maintenance quickly tells you about the condition of your system—part of a good condition-based monitoring routine.

- Cost Savings Over Time: Protecting your equipment from damage saves money on repairs and replacements. Plus, by catching debris early, you can avoid costly failures or breakdowns.

- Versatility for Multiple Systems: Whether you’re working with hydraulic systems, gearboxes, or industrial magnetic filters, magnetic plugs help maintain equipment in trucks, construction gear, and factory machines.

For local users in the U.S., magnetic plugs are a smart, cost-effective way to keep your vehicles and industrial gear running longer, cleaner, and more reliably.

Common Applications and Real World Use Cases

Magnetic plugs are widely used across various industries and everyday machinery in the worldwide. Their main job is to catch metal debris, like tiny ferrous particles, preventing damage and reducing wear in engines and machines.

Common Applications

- Engine oil sump debris trap: Magnetic drain plugs are often installed in car and truck engines to capture metal shavings before they circulate and cause engine wear.

- Transmission fill plug: Using a magnetic plug in transmissions helps keep gears clean by attracting metal bits that naturally appear during gear shifts.

- Hydraulic system maintenance: Hydraulic systems rely on clean fluid to operate smoothly. Magnetic plugs filter out metal particles to prevent system failures.

- Gearbox vent plug: Gearboxes in industrial and agricultural equipment often use magnetic plugs to trap metal fragments, extending the life of the gears.

- Industrial magnetic filter setups: In heavy machinery and manufacturing plants, magnetic plugs serve as the first line of defense against metal contamination.

Real World Use Cases

- Automotive repair shops: Many mechanics recommend magnetic drain plugs for oil changes to monitor the engine’s health through condition-based monitoring.

- Construction and farming equipment: Heavy gear like bulldozers and tractors use magnetic plugs to reduce unexpected downtime by trapping harmful debris.

- Marine engines: Saltwater corrosion combined with engine wear makes magnetic plugs essential for boat maintenance.

- Industrial gearboxes: Factories use magnetic plugs to capture wear particles, helping with preventive maintenance and avoiding costly repairs.

By catching metal particles early, magnetic plugs play a crucial role in keeping equipment lasting longer and running better in everyday U.S. applications—from your family car to large industrial machines.

Installation Maintenance and Troubleshooting Guide

Installing a magnetic plug is straightforward, but doing it right ensures you get the full benefits of this industrial magnetic filter. Here’s how to handle installation, maintenance, and common troubleshooting for magnetic drain plugs and similar types.

Installation Steps

- Locate the right plug port: Usually, magnetic plugs replace your traditional transmission fill plug, gearbox vent plug, or drain plug in oil sumps.

- Remove old plug carefully: Make sure to keep the area clean so no dirt enters the system during replacement.

- Install the magnetic plug: Screw the plug in snugly, but don’t overtighten—it’s important to maintain a proper seal without damaging threads.

- Double-check for leaks: After installation, run your engine or hydraulic system and inspect for any leaks around the plug.

Maintenance Tips

- Regular inspection: Check the magnetic plug during routine oil changes or hydraulic system maintenance.

- Clean trapped debris: Remove the magnetic plug periodically to wipe away the ferrous particle filter buildup. This helps prevent engine wear and prolong pump and gearbox life.

- Keep an eye on debris size and quantity: This is part of condition-based monitoring that can warn you about early system damage.

Troubleshooting Common Issues

- Plug leaking: If you notice oil or fluid leakage, ensure the plug is tightened correctly and the sealing washer or O-ring is intact.

- Reduced magnetic performance: If the plug isn’t collecting as much debris, it may be damaged or the neodymium magnet plug inside could be weakening. Replace if necessary.

- Plug difficult to remove: Use the proper tools and avoid forcing the plug to prevent thread damage.

Following these steps will keep your magnetic plug functioning efficiently and protect your engine or hydraulic system from premature wear and costly repairs.

For more on magnets and magnetic components used in similar applications, check out What Are Magnets Made Of and Magnetic Materials for Sensor Applications.

Contach us to choose the suitable magnets for your magnetic plugs.

Leave A Comment