What Exactly Is an Arc Magnet Breaking Down the Basics

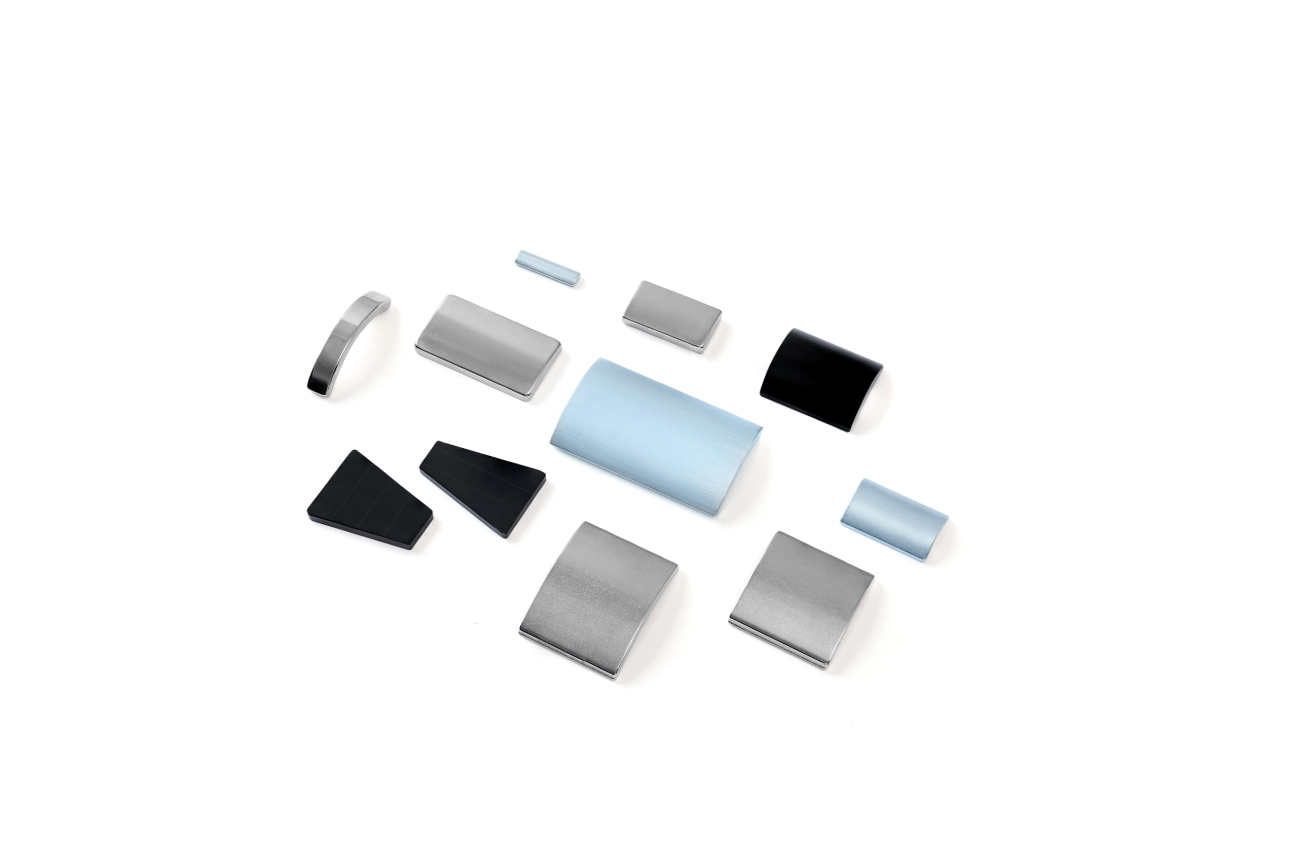

Are you wondering what makes an arc magnet different from other types of magnets? At its core, an arc magnet is a curved segment magnet designed to fit precisely into circular or cylindrical assemblies. Unlike tile-shaped magnets or straight blocks, arc magnets are specially shaped to match the curvature of rotors and stators used in motors, generators, and other rotary devices.

What is an Arc Magnet

- Shape: Curved or arc-like to conform to circular structures

- Material: Usually made from high-strength rare earth magnets such as Neodymium (NdFeB) or Samarium Cobalt (SmCo)

- Magnetization: Often magnetized radially or axially depending on application needs

Imagine standard block magnets as flat puzzle pieces, while arc magnets are curved pieces that perfectly fit into round puzzles like motor rotors. This design ensures uniform magnetic flux distribution, which boosts efficiency.

Comparing Arc Magnets and Other Magnet Types

| Magnet Type | Shape | Typical Use | Magnetic Flux Benefit |

|---|---|---|---|

| Block Magnet | Rectangular/Tile-shaped | General purposes, simple motor designs | Less uniform in circular assemblies |

| Arc Magnet | Curved segment | Rotors, stators, rotary machines | Perfect fit for smooth flux distribution |

| Ring Magnet | Circular ring | Specialized applications like sensors | Continuous magnetic field |

Key Specifications and Materials

- Materials: Most arc magnets are composed of NdFeB for high magnetic strength or SmCo for high temperature tolerance.

- Grades: Vary from N35 to N55 for NdFeB, depending on strength needs.

- Sizes: Customizable to fit different rotor diameters and segment angles.

- Magnetization: Radial magnetization is common for efficient motor performance.

Common Misconceptions

- Arc magnets are often assumed to be just bent strip magnets — but their magnetic properties and quality control require precision shaping and magnetization.

- Some believe only NdFeB materials are used; SmCo is also popular for challenging environments.

- Another myth is that arc magnets are less versatile — in fact, their customizability makes them ideal for many advanced applications.

NBAEM’s Precision in Arc Segments Magnet

At NBAEM, we specialize in producing highly precise arc magnet segments. Our advanced manufacturing process guarantees exact curvature and consistent magnetic properties, so each segment flawlessly fits your design. This precision minimizes magnetic losses and mechanical imbalance, enhancing overall system efficiency.

Want to see how arc magnets can transform your application? Contact NBAEM to explore custom solutions tailored to your project needs.

How Are Arc Magnets Made A Step-by-Step Manufacturing Process

Arc magnets start with high-quality raw materials like NdFeB (neodymium-iron-boron) and SmCo (samarium-cobalt), both known for their strong magnetic properties and durability. These rare earth elements form the backbone of powerful, reliable magnets used across many industries.

The manufacturing process begins with alloy sintering. Here, the raw materials are melted and cooled to create a solid magnetic alloy. This step ensures the magnet’s internal structure is dense and uniform, which is crucial for maintaining high magnetic flux density.

Next comes precise machining. The solid alloy is cut and shaped into curved segments, matching the unique arc magnet profile. NBAEM uses advanced CNC machines to achieve tight tolerances, allowing for perfect fits in motors or generators.

Then, the magnets undergo magnetization, where a strong magnetic field aligns the material’s magnetic domains. This step defines the direction of magnetization—often radial in arc magnets—to maximize efficiency in rotary applications.

After magnetization, the magnets receive protective coatings. These coatings guard against corrosion and wear, extending the motor or device’s lifespan, especially in demanding environments.

At NBAEM, quality control is a top priority. Each arc segment is tested for magnetic strength, dimensions, and surface finish to meet strict standards. This thorough checking helps prevent issues down the line in assembly or performance.

Finally, arc magnets can be customized with multi-pole designs and different grades to fit specific use cases. Whether for electric vehicle motors or industrial turbines, NBAEM’s flexibility ensures you get the best magnet for your project.

For details on high-performance SmCo magnets used in some arc magnet applications, visit NBAEM’s guide on high-performance SmCo magnets.

Why Choose Arc Magnets Key Advantages and Performance Benefits

Arc magnets offer several clear benefits that make them a top choice, especially in the U.S. market where efficiency and reliability matter.

High Magnetic Flux Advantages

Arc magnets provide a strong magnetic flux density. This means they deliver powerful magnetic fields in a curved segment, which fits perfectly in rotating motors and generators. High magnetic flux ensures better performance and responsiveness, crucial for permanent motor magnets used in electric vehicles and industrial machinery. If you want to dive deeper into magnetic flux fundamentals, check out what is meant by magnetic flux.

Efficiency Gains in Motor Applications

Thanks to their shape and radial magnetization, arc magnets improve motor efficiency by optimizing magnetic flow and reducing energy loss. Motors using these curved segment magnets require less power for the same output, making them ideal for EV motors, turbines, and other high-performance equipment.

Durability and Temperature Tolerance

Arc magnets made with rare earth materials like NdFeB and SmCo maintain strong magnetic properties even under high temperatures and tough operating conditions. This durability reduces downtime and maintenance costs, a huge plus for applications like renewable energy or industrial sensors.

Cost-Effectiveness and Production Scalability

With precision manufacturing techniques from NBAEM, arc magnets can be produced consistently at scale without compromising quality. This keeps costs competitive and helps projects meet deadlines. Plus, multi-pole and custom magnet options allow flexibility in design, letting you tailor performance without overspending.

Comparison of Arc with Other Magnet Shapes

Compared to tile-shaped or block magnets, arc magnets contour perfectly to the motor’s rotor, leading to smoother operation and less vibration. This shape also improves magnetic flux concentration, outperforming conventional magnets in many motor and generator setups.

NBAEM’s Expertise and Project Examples

NBAEM specializes in producing high-strength rare earth arc magnets with tight quality control. Their experience with custom arc magnets in sectors like electric vehicles and robotics shows their ability to deliver performance that meets demanding U.S. industry standards.

In short, arc magnets offer strength, efficiency, durability, and cost savings, making them a smart choice for anyone needing high-performance permanent motor magnets.

Real-World Applications Where Arc Magnets Shine

Arc magnets are a game-changer in many industries, especially here in the U.S., where efficiency and performance matter. Their curved segment shape fits perfectly in motors and generators, including electric vehicles (EVs) and wind turbines. This design helps boost magnetic flux density, which means stronger and more reliable power generation.

You’ll also find arc magnets in magnetic couplings, offering seal-less torque transfer solutions that reduce wear and maintenance. This is a big plus in systems where durability and smooth operation are critical.

In sensors and separators, arc magnets help improve precision and reliability, making them ideal for applications ranging from industrial equipment to recycling technologies.

Emerging tech like drones, robotics, and renewable energy systems are also tapping into the power of arc magnets. Their customizability and high-strength rare earth materials like NdFeB segments make them a favorite for new-age innovations.

NBAEM has a notable case study where integrating high-quality arc magnets into motor systems led to significant efficiency improvements, proving these magnets are not just theory—they deliver real savings and performance benefits in everyday applications.

If you want to dive deeper into magnetic properties that affect performance, check out NBAEM’s guide on what is magnetic flux.

Selecting the Right Arc Magnet Buyer’s Guide from NBAEM

Choosing the right arc magnet can make a huge difference in your project’s success. Here are the main factors to keep in mind:

- Size and shape: Make sure the magnet fits your application perfectly. Arc magnets come in various curved segment sizes, so measure carefully and consider thickness and arc angle.

- Magnet grade: NdFeB (neodymium) and SmCo magnets have different strengths and temperature tolerances. Pick a grade that matches your performance and environment needs.

- Magnetization direction: Radial magnetization is common in arc magnets, especially for motors. Confirm the magnet’s polarization fits how your device will use magnetic flux.

- Operating environment: Temperature, humidity, and corrosion factors affect magnet life and strength. Check if you need special coatings or higher temperature grades.

NBAEM offers an easy-to-use online calculator tool to help you quickly find the right size and specifications. This tool takes the guesswork out, giving reliable dimensions based on your input.

Watch out for common pitfalls

- Mixing up magnet grades that won’t hold up in your environment

- Overlooking precise alignment during assembly (it can weaken performance)

- Ignoring coating requirements for protection against corrosion

Sourcing tips for US buyers

Working with a supplier like NBAEM, known for precision in custom arc magnets and strict quality control, ensures reliable delivery and consistent magnet strength. Verify supplier certifications and ask about sample availability before placing large orders. Locally compliant materials and testing standards are key for smooth import and usage in the US market.

Following these guidelines will help you pick the perfect arc magnet whether you’re building motors, generators, or innovative tech in robotics or renewable energy.

Leave A Comment