If you work in precast concrete production, you know how tricky it can be to get those crisp, clean chamfered edges without damaging your formwork or slowing down your workflow. That’s where magnetic chamfers come in—a smart, reusable solution that clamps right onto steel formwork using powerful neodymium magnets, making precise 45-degree bevels easier and faster than ever. In this post, we’ll break down what magnetic chamfer is, why it’s transforming precast plants worldwide, and how trusted suppliers like NBAEM are leading the way with durable, high-quality magnetic components designed for efficiency and longevity. Ready to upgrade your formwork game? Let’s dive in.

What Is Magnetic Chamfer? A Comprehensive Definition

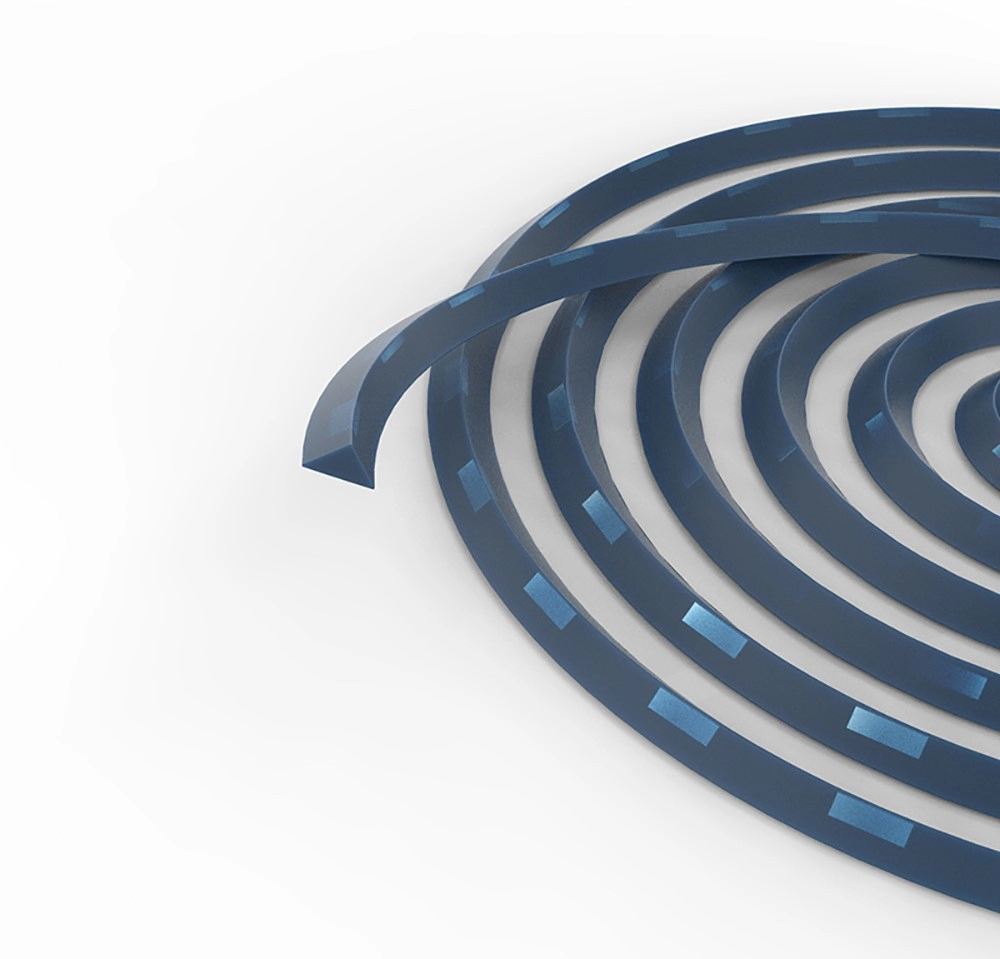

A magnetic chamfer is a specialized accessory used in precast concrete formwork to create clean, precise beveled edges, known as chamfers, on concrete panels, beams, and columns. Essentially, it combines a steel chamfer, allowing it to securely attach to steel formwork surfaces without the need for nails or clamps. This setup ensures effortless placement, adjustment, and removal, streamlining the concrete forming process while delivering consistent

Types of Magnetic Chamfers: Choosing the Right Fit for Your Operation

Magnetic chamfers come in various types to suit different precast concrete needs. The most common are steel magnetic chamfer strips, known for their durability and strong hold. These steel magnetic chamfers come in multiple sizes, typically designed as triangle magnetic strips to create clean, precise beveled concrete edges on wall panels, beams, and columns.

The most commen size of triangle magnetic strips we make are: 10*10*14, 15*15*21, 20*20*28, 25*25*35, there is also trapezoid size .

For projects involving curved or irregular shapes, rubber chamfers(flexible chamfer) offer flexibility that steel can’t provide. These rubber magnetic chamfers easily conform to curved forms, making them ideal for decorative precast elements or complex infrastructure parts.

Besides standard options, specialized magnetic chamfers can be custom-sized or designed to match unique formwork requirements. Whether you need different angles, lengths, or magnet strengths, many suppliers, including NBAEM, offer tailored solutions to fit your specific precast system.

Choosing the right magnetic chamfer depends on your operation’s needs—steel for strength and repeatability, rubber for flexibility, and custom shapes for specialized projects. Each type enhances your formwork setup by providing reliable, reusable concrete bevels that speed up production and improve quality.

How Magnetic Chamfers Work in Precast Concrete Formwork

Magnetic chamfer simplifies the process of shaping beveled edges in precast concrete by sticking firmly to steel formwork using high-quality magnets. Here’s a quick rundown of how it works, from setup to demolding:

- Positioning: The magnetic chamfer strip is aligned along the edge of the steel formwork where the bevel is needed. Its strong magnetic steel strip or neodymium magnets hold it securely in place without extra fasteners.

- Pouring Concrete: Once positioned, concrete is poured into the formwork, flowing around the magnetic chamfer. The chamfer defines the beveled edge, creating a smooth, precise reveal strip on the finished panel.

- Curing: During curing, the chamfer stays fixed thanks to the magnetic pull force—this strong hold prevents any movement that could spoil the edge quality.

- Demolding: After the concrete cures, the magnetic chamfer is easily removed by lifting it off the steel formwork. The magnets allow quick separation without damaging the concrete or forms.

The physics behind the magnetic hold comes down to the attractive force between the magnet and the steel base. Neodymium chamfer magnets, for example, deliver powerful pull force that can resist the pressure and vibrations during concrete pouring, ensuring the magnet stays firmly attached.

Magnetic chamfers fit seamlessly into precast systems by offering reusable, adjustable solutions that reduce setup time and improve edge accuracy. For instance, many precast plants use magnetic chamfers on wall panels and beams, benefiting from faster changeovers and less wear on formwork components.

Key Benefits of Using Magnetic Chamfers in Production

Magnetic chamfer tools bring clear advantages to precast concrete production, boosting efficiency, quality, and safety.

Efficiency Gains and Cost Savings

- Quick Installation: Magnets hold firmly without clamps or nails, speeding up setup and reducing labor time.

- Reusable Design: Steel and rubber magnetic chamfers can be reused across multiple projects, cutting down material costs.

- Less Damage: No hammering or drilling means fewer formwork repairs and longer tool life.

Quality Improvements and Safety Considerations

- Consistent Edges: Magnetic chamfers create uniform beveled concrete edges every time, improving the finish of precast wall panel edges and beams.

- Better Safety: Eliminating nails and clamps reduces on-site injuries and makes handling easier.

- Reliable Hold: Neodymium chamfer magnets provide strong magnetic force to prevent formwork movement during concrete pour.

NBAEM’s Role in Magnet Quality and Durability

NBAEM is a top supplier known for high-quality neodymium magnets used in magnetic formwork systems. Their magnets feature:

- Strong Magnetic Pull Force: Ensures secure attachment on steel strips.

- Durability: Resistant coatings protect against corrosion and wear, maintaining magnet strength over time.

- Customization: Size and shape options to fit all types of precast concrete

Applications in Precast Concrete: Where It Shines

Magnetic chamfer finds its strongest footing in precast concrete projects, especially in shaping clean, precise edges on wall panels, beams, and columns. These beveled concrete edges created with magnetic steel strips provide a sharp, uniform reveal that improves both the look and structural integrity of the finished product.

Several industry sectors benefit from this technology. Commercial construction, infrastructure, and architectural precast manufacturers rely on magnetic chamfer systems to speed up production while ensuring consistent quality across large-volume runs. Its reusability and strong hold make it ideal where tight tolerances and quick turnaround are essential.

Beyond standard uses, magnetic chamfers show great promise in advanced decorative concrete applications. Intricate patterns and complex bevels can be formed accurately without the hassle of traditional nailed chamfers. Infrastructure projects, such as bridges and tunnels, also leverage magnetic formwork systems for durable, clean edges that withstand exposure and heavy use.

Thanks to options like rubber magnetic chamfer strips for curved forms and customizable sizing, this system adapts well across a wide range of precast concrete needs—making it a standout choice for both routine builds and specialized projects.

Installation and Maintenance Best Practices

Proper installation and regular maintenance are key to getting the most out of your magnetic chamfer system.

Setup Guide and Handling Precautions

- Clean the surface: Before attaching the magnetic steel strip or rubber magnetic chamfer, make sure the formwork is clean and free of debris to ensure a strong magnetic hold.

- Position precisely: Align the magnetic chamfer carefully along the edge where the beveled concrete reveal is needed. The magnets provide firm grip, but proper positioning ensures perfect bevels.

- Handle with care: Neodymium chamfer magnets are powerful but brittle. Avoid dropping or striking them against hard surfaces to prevent chipping or loss of magnetism.

- Use protective gloves: When handling magnetic formwork systems, gloves protect your hands and help with better grip.

Troubleshooting Common Issues

- Weak magnetic hold: Check for dust or rust on either the magnet or steel surface. Clean both to restore full pull force.

- Misaligned bevels: Double-check placement before pouring concrete. Even slight shifts can affect the final edge quality.

- Adhesion problems with rubber strips: Ensure rubber

Comparing Magnetic Chamfers to Traditional Methods

When it comes to creating clean, beveled concrete edges, magnetic chamfers offer clear advantages over traditional options like plastic or nailed chamfers. Unlike plastic chamfer strips that can crack or break after repeated use, magnetic chamfers—especially those using durable magnetic steel strips—are reusable and maintain consistent quality over many cycles. Nailed chamfers, meanwhile, require time-consuming installation and can damage formwork during removal.

Magnetic chamfer systems also provide much more flexibility compared to fixed formwork bevels. They can quickly be repositioned or moved between different projects without the hassle of extra tools or fasteners. This adaptability is a huge time saver in busy precast shops or onsite work.

Here’s a quick pros and cons overview for magnetic chamfer versus traditional chamfer methods:

| Feature | Magnetic Chamfer | Plastic/Nailed Chamfer | Fixed Formwork Bevel |

|---|---|---|---|

| Reusability | High, with strong magnets | Low to moderate, prone to wear | High but limited to one shape |

| Installation Speed | Fast, simple placement |

Sourcing Quality Magnetic Chamfers: What to Look For

When sourcing magnetic chamfer for your precast concrete projects, quality and reliability are key. First, look for suppliers who offer high-grade magnetic steel strips and neodymium chamfer magnets known for strong pull force and durability. Check for consistency in manufacturing, corrosion resistance, and the type of magnet used, since these factors directly impact performance and lifespan.

Cost is another important factor. While it’s tempting to go for the cheapest option, remember that quality magnetic chamfer ensures better efficiency and fewer replacements. If you are buying in bulk, many suppliers offer discounts, but always weigh cost against material strength and magnet retention rates to avoid frequent losses or delays.

NBAEM stands out as a leading supplier in this space, delivering durable precast accessories like shuttering magnet tools with reliable magnetic formwork systems. Their products combine quality magnet materials and expert craftsmanship, providing excellent value and consistent performance.

Leave A Comment