Definition of Magnetic Permeability

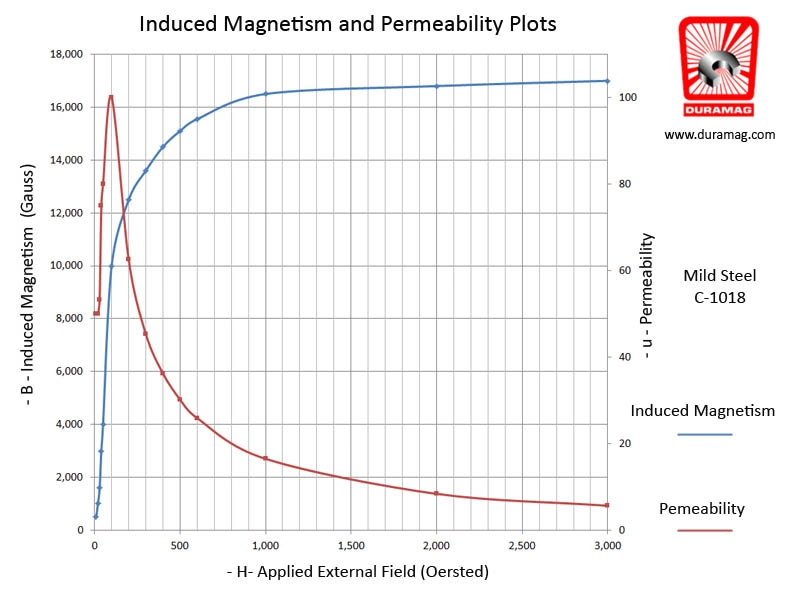

Magnetic permeability is a fundamental property that measures a material’s ability to support the formation of a magnetic field within itself. Scientifically, it is defined as the ratio of the magnetic flux density (B) to the magnetic field intensity (H), expressed as μ = B / H. In simple terms, it indicates how easily a magnetic field can penetrate and exist inside a material.

Magnetic permeability differs from magnetic susceptibility and relative permeability. While magnetic susceptibility refers to how much a material will become magnetized in response to an applied magnetic field, relative permeability is the ratio of a material’s permeability to the permeability of free space (vacuum). Understanding these distinctions helps clarify how materials interact with magnetic fields in various applications.

Physical Meaning and Units of Magnetic Permeability

Magnetic permeability relates two key quantities: the magnetic flux density (B) and the magnetic field intensity (H). Simply put, B represents the amount of magnetic field passing through a material, while H is the strength of the magnetic field applied to that material. Magnetic permeability (μ) shows how much a material allows magnetic lines of force to pass through it, calculated by the formula μ = B / H.

In terms of units, magnetic permeability is measured in Henries per meter (H/m) in the SI system. There are two types to keep in mind:

- Absolute permeability (μ): the actual permeability value for a material.

- Relative permeability (μr): a dimensionless ratio comparing a material’s permeability to the permeability of free space.

The permeability of free space, also called the permeability of vacuum (μ0), is a constant valued at approximately 4π × 10⁻⁷ H/m. This constant is the baseline used to understand how materials respond to magnetic fields compared to empty space.

Types of Magnetic Materials Based on Permeability

Magnetic materials are mainly classified into three types based on their magnetic permeability: diamagnetic, paramagnetic, and ferromagnetic.

- Diamagnetic materials have very low permeability, often less than that of free space (μ0). They slightly repel magnetic fields. Examples include copper, bismuth, and gold. Their permeability is close to 1 or even slightly less when expressed as relative permeability (μr).

- Paramagnetic materials have a relative permeability slightly greater than 1. They weakly attract magnetic fields but don’t retain magnetization when the field is removed. Aluminum and platinum are common examples. These materials exhibit a small positive permeability enhancement compared to diamagnetic materials.

- Ferromagnetic materials show very high permeability, sometimes thousands of times that of free space. These materials, like iron, cobalt, and nickel, strongly attract and can retain magnetic fields, making them critical for many magnetic applications. Their permeability varies widely based on composition and processing but is always much greater than 1.

The permeability directly affects how materials respond to magnetic fields:

- High permeability means the material channels magnetic flux well, boosting magnet performance and efficiency.

- Low permeability materials offer minimal magnetic response and can be used where magnetic interference needs to be minimized.

Understanding these differences helps in selecting the right magnetic material for your application, whether it’s for transformers, sensors, or shielding. For more on magnetic materials and their magnetic properties, check out our guide on types of magnetic materials and the differences between paramagnetic and diamagnetic materials.

Factors Affecting Magnetic Permeability

Magnetic permeability isn’t a fixed value—it changes depending on several key factors:

- Temperature: As temperature rises, the magnetic permeability of most materials drops. For example, ferromagnetic materials lose their high permeability near their Curie temperature, where they stop being magnetically ordered.

- Frequency of the Magnetic Field: At higher frequencies, some materials show reduced permeability due to effects like eddy currents and hysteresis. This means a material that works great at low frequencies might not perform as well at radio or microwave frequencies.

- Material Composition and Structure: The type of elements in the material and its internal structure strongly influence permeability. Purity, grain size, and crystal orientation can all change how easily magnetic fields pass through.

- External Influences: Stress or mechanical deformation can alter the magnetic domains inside a material, affecting permeability. Also, when a material approaches magnetic saturation—meaning most of its magnetic domains are aligned—its permeability decreases because it can’t support a stronger magnetic field.

Understanding these factors helps when selecting magnetic materials for specific applications, especially in the U.S. market where performance under different conditions matters a lot.

Measurement of Magnetic Permeability

Measuring magnetic permeability accurately is key to understanding a material’s magnetic behavior. Common techniques include vibrating sample magnetometers (VSM) and impedance methods. VSMs work by vibrating a sample in a magnetic field and detecting the magnetic response, offering precise permeability readings especially for small or thin samples. Impedance methods involve applying an alternating current to a coil wrapped around the material and analyzing how the material affects the coil’s resistance and inductance.

When measuring permeability, practical factors matter:

- Sample shape and size can influence results due to edge effects or non-uniform fields.

- Frequency of the applied magnetic field affects measurements since permeability can change with frequency.

- Temperature control is important because permeability varies with temperature.

- Ensuring the material isn’t near magnetic saturation helps avoid distortion of readings.

Challenges arise from the material’s magnetic non-linearity and internal stress, which can cause variations in permeability. Additionally, environmental magnetic noise and instrument calibration play roles in measurement accuracy. Despite these challenges, with the right equipment and setup, reliable magnetic permeability measurements provide essential data for magnetic material applications.

Applications of Magnetic Permeability in Industry and Technology

Magnetic permeability plays a big role in many industries here in the U.S., especially where magnetic materials are key. For example, electrical transformers and inductors rely on materials with the right permeability to efficiently channel magnetic fields and reduce energy loss. Without the correct permeability, these devices can’t perform as well or last as long.

Magnetic permeability also matters a lot in magnetic shielding. When you want to protect sensitive electronics from stray magnetic fields, materials with high or tailored permeability help block or redirect those fields. This is crucial in aerospace, medical devices, and even consumer electronics.

Another major area is data storage and magnetic sensors. Hard drives and many sensor technologies depend on materials with specific permeability values to accurately read or store magnetic signals. The better the control over permeability, the higher the performance and reliability of these devices.

Companies like NBAEM provide magnetic materials with precise permeability ratings tailored for these applications. Their materials help U.S. manufacturers meet tight specifications by ensuring consistent magnetic behavior, which directly impacts the efficiency and durability of end products. Whether it’s for power systems, shielding, or sensors, using materials from NBAEM with engineered permeability can make a noticeable difference in performance.

Magnetic Permeability in Advanced Materials

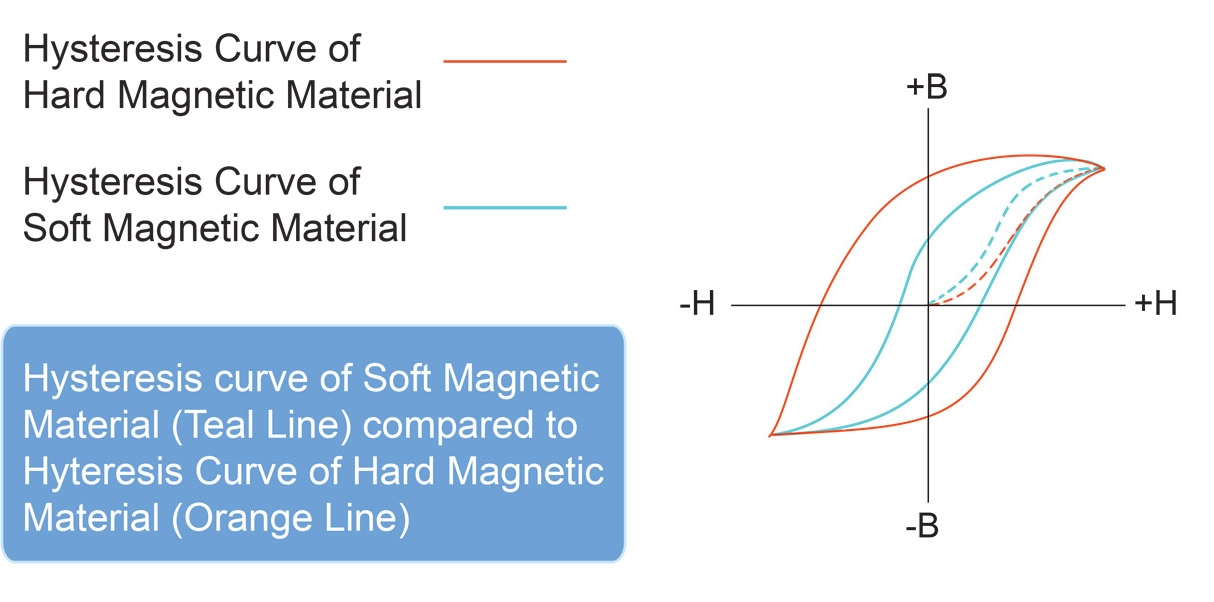

Magnetic permeability plays a crucial role in distinguishing soft and hard magnetic materials. Soft magnetic materials, like silicon steel or certain ferrites, have high permeability, meaning they easily support magnetic fields and quickly respond to changes. These are ideal for transformers, inductors, and electromagnets where efficient magnetization and demagnetization are needed. In contrast, hard magnetic materials, such as rare-earth magnets, have lower permeability but retain magnetization longer, making them key for permanent magnets.

Recent innovations focus on engineering magnetic materials with tailored permeability to meet specific demands. Scientists are developing composites and nano-structured materials that offer controlled permeability, improving performance in devices like high-frequency transformers or compact energy storage systems. These advances enable better control over magnetic losses and energy efficiency.

The importance of magnetic permeability is especially high in emerging technologies like electromagnetics and energy devices. For example:

- Efficient inductors and transformers in renewable energy systems require materials with optimized permeability for minimal energy loss.

- Electric vehicle motors benefit from magnetic materials engineered for specific permeability to improve torque and reduce size.

- Advanced sensors and actuators rely on materials where permeability can be finely tuned for precision and responsiveness.

Understanding the permeability of modern magnetic materials helps manufacturers in the U.S. market design better products for industries ranging from automotive to renewable energy. For more on magnetic materials and their classifications, check out Types of Magnetic Materials and explore recent research at Recent Advances in Magnetic Material Research.

Leave A Comment