Defining Magnetic Flux

Magnetic flux is a measure of the total magnetic field passing through a given surface. Scientifically, it’s defined as the product of magnetic flux density and the area it penetrates, considering the angle between them. In other words, it tells you how much of the magnetic field actually flows through a surface.

For beginners, think of magnetic flux as “how many magnetic field lines go through a surface.” If more lines pass through, the magnetic flux is higher. If fewer pass through, it’s lower.

It’s important to distinguish between related terms:

| Term | Meaning | Unit |

|---|---|---|

| Magnetic Flux (Φ) | Total magnetic field passing through a surface | Weber (Wb) |

| Magnetic Field (H) | Strength of the magnetic influence | Ampere per meter (A/m) |

| Magnetic Flux Density (B) | Magnetic flux per unit area | Tesla (T) = Wb/m² |

- Magnetic field is about the intensity of the magnetic effect.

- Magnetic flux density describes how concentrated the magnetic flux is in a given area.

- Magnetic flux looks at the bigger picture — the total effect over an area.

In practical terms, while magnetic flux density tells you how strong a magnet is at a certain spot, magnetic flux tells you the overall magnetic influence through a space or object. This distinction is crucial in engineering applications ranging from transformer design to rare earth magnet performance (learn more here).

The Physics Behind Magnetic Flux

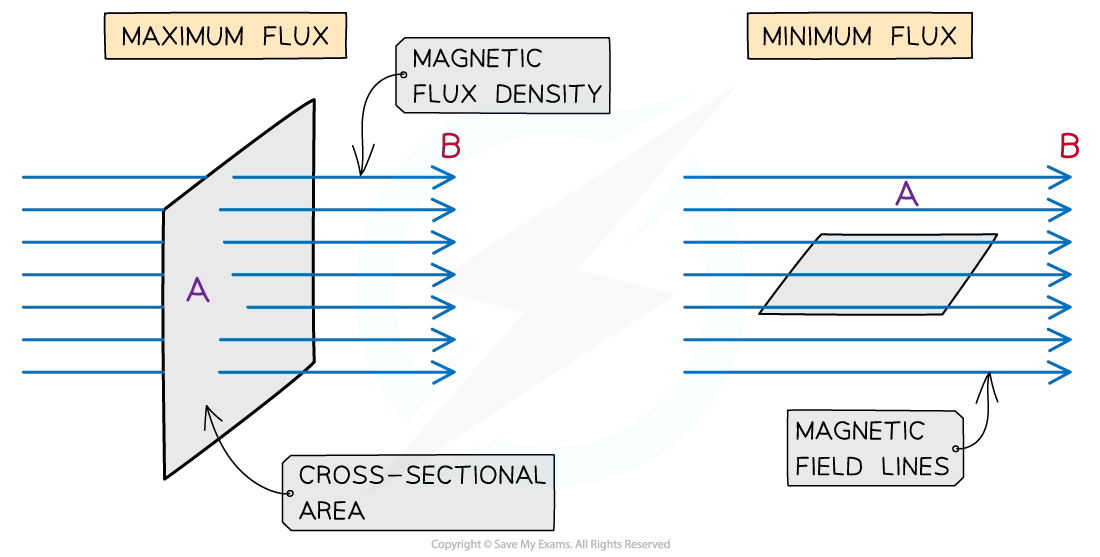

Magnetic flux is all about how much of a magnetic field passes through a given surface. You can picture magnetic field lines as invisible threads around a magnet or current-carrying wire. The more lines that pass through an area, the greater the magnetic flux there. If the surface is tilted, fewer lines cut through it, which means less flux.

In physics, we measure magnetic flux in Webers (Wb), the SI unit. One Weber equals the total magnetic field that passes through a one-square-meter area when the magnetic flux density is one tesla. The symbol for magnetic flux is Φ.

Magnetic flux is a way to put a number on the “amount” of magnetism passing through something, which makes it easier to compare different magnetic setups, calculate electrical generation, and design devices like motors, generators, and transformers.

Mathematical Expression of Magnetic Flux

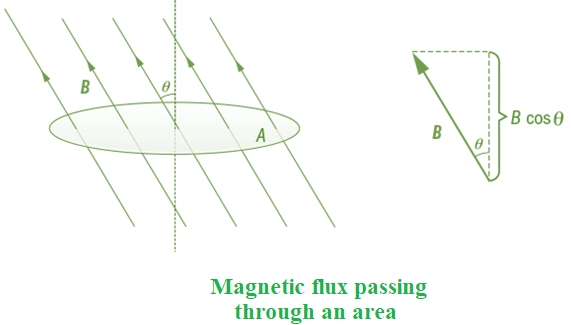

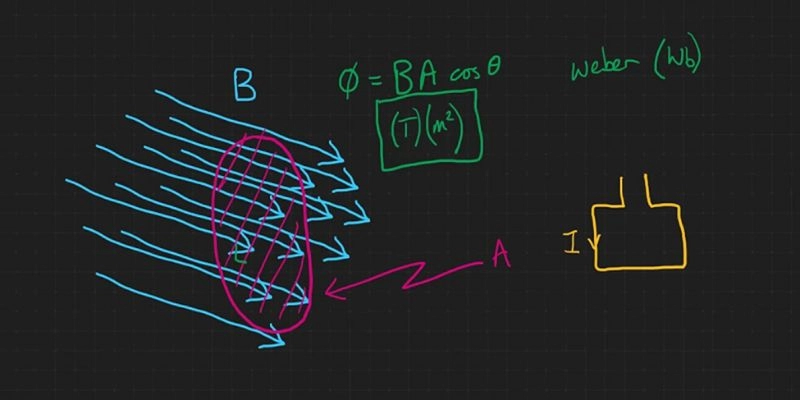

The magnetic flux (Φ) is calculated using the formula:

Φ = B · A · cos(θ)

Here’s what each part means:

B – Magnetic flux density, measured in teslas (T). It tells you how strong the magnetic field is.

A – The area the magnetic field passes through, measured in square meters (m²).

θ – The angle between the magnetic field direction and the surface’s normal (an imaginary line perpendicular to the surface).

If the field is perfectly perpendicular to the surface (θ = 0°), cos(θ) = 1, and the flux is at its maximum. If the field is parallel to the surface (θ = 90°), cos(θ) = 0, meaning no flux passes through.

Example:

Imagine a flat coil with an area of 0.05 m² placed in a uniform magnetic field of 0.8 T. If the field is at a 30° angle to the coil:

Φ = 0.8 × 0.05 × cos(30°)

Φ ≈ 0.8 × 0.05 × 0.866

Φ ≈ 0.0346 Wb (webers)

This tells us the total magnetic field “cutting through” the coil’s area at that angle.

Measuring Magnetic Flux

Measuring magnetic flux is all about knowing how much of a magnetic field is passing through a given area. In practical work, this is done using devices like a fluxmeter or Hall effect sensors. A fluxmeter is designed to directly measure the total magnetic flux in Webers (Wb), making it ideal for lab testing and inspection. Hall effect sensors, on the other hand, detect changes in magnetic field strength and can be used in real-time monitoring setups.

In the U.S., industries like transformer manufacturing, motor production, and magnetic material testing rely heavily on accurate magnetic flux measurements. This ensures that components meet performance standards and that magnets or coils produce the exact magnetic effect required. In quality control, these measurements help detect faults like underperforming magnets, improper coil winding, or material defects—saving costs and preventing equipment failures.

Common techniques for measuring magnetic flux include:

- Direct measurement with a fluxmeter for precise readings in research and calibration.

- Hall effect sensors for field testing and automation systems.

- Search coils for detecting flux changes in rotating machinery or transformers.

Accurate measurement means better product consistency, improved efficiency, and compliance with safety and performance standards.

Applications and Importance of Magnetic Flux

Magnetic flux plays a big role in how many electrical devices work. In electrical engineering, it’s at the core of how transformers, motors, and generators operate. In a transformer, magnetic flux transfers energy between coils without physical contact. In motors and generators, changes in magnetic flux create motion or electricity through electromagnetic induction.

When it comes to selecting magnetic materials, knowing their flux capabilities is important. Materials with high magnetic permeability can channel magnetic flux more efficiently, improving performance and reducing energy loss. This matters in industries like automotive manufacturing, renewable energy, and electronics production.

We use technology based on magnetic flux every day without thinking about it:

- Smartphones and laptops rely on components influenced by magnetic flux for wireless charging and speakers.

- MRI machines in hospitals use strong magnetic flux to create detailed body images.

- Induction cooktops heat food by changing magnetic flux through a cooking vessel.

- Wind turbines generate power by converting magnetic flux changes into electricity.

From small electronics to large power plants, controlling and using magnetic flux is a key part of making devices efficient, reliable, and safe.

Magnetic Flux in Magnetic Materials

Magnetic flux plays a big role in understanding how different magnetic materials perform. Materials like neodymium, ferrite, and Alnico supplied by NBAEM vary in how much magnetic flux they can handle and maintain. This depends on their magnetic permeability, saturation point, and resistance to demagnetization. For instance, neodymium magnets produce a very high magnetic flux for their size, making them ideal for compact, high-performance applications like motors and speakers, while ferrite magnets offer lower flux but better temperature stability and cost efficiency.

When choosing materials for industrial use, engineers look at:

- Magnetic flux density capability (how much magnetic field per unit area the material can carry)

- Operating temperature range (some materials lose flux when heated — see what is the effect of heating neodymium magnets)

- Coercivity (resistance to flux loss from opposing magnetic fields)

- Application needs (strong flux for motors vs stable flux for sensors)

For example, in power transformers, magnetic cores with high flux capacity reduce energy loss and improve efficiency, while in magnetic sensors, consistent flux response is more important than maximum strength. NBAEM’s range of materials lets manufacturers balance these factors so the final product meets performance, cost, and durability targets.

Common Misconceptions About Magnetic Flux

A lot of people mix up magnetic flux with magnetic field strength, but they’re not the same thing. Magnetic field strength (measured in tesla) tells you how strong the field is at a point, while magnetic flux measures the total amount of magnetic field passing through a given area.

Two key points to remember:

- Direction matters – Magnetic flux depends on the angle between the magnetic field and the surface. If the field is parallel to the surface, the flux is zero.

- Area matters – A larger surface facing the field gathers more flux than a small one, even if the field strength is the same.

Here’s a quick breakdown:

| Term | What It Means | Unit |

|---|---|---|

| Magnetic Flux (Φ) | Total magnetic field through an area | Weber (Wb) |

| Magnetic Field Strength (B) | Intensity of magnetic field at a point | Tesla (T) |

| Flux Dependence | Field strength, area size, and angle | — |

Tip: Always consider both the field’s orientation and the size of the area when talking about flux. This is especially important in applications like designing transformers, motors, or magnetic sensors.

FAQs

What happens to magnetic flux in a closed circuit

In a closed magnetic circuit (like inside a transformer core), magnetic flux flows through the material with minimal loss because the path is continuous and usually made of a high-permeability material. This setup helps keep flux leakage low, which improves efficiency. If there’s a gap in the circuit, flux will drop because air has much lower magnetic permeability than the core material.

How does temperature affect magnetic flux in materials

Temperature changes can impact magnetic flux because magnetic properties of materials shift with heat.

- Low temperatures – Magnetic materials tend to hold flux more effectively.

- Higher temperatures – Magnetic strength often weakens, reducing the flux.

- Above Curie temperature – Materials lose ferromagnetic properties completely and magnetic flux can’t be maintained.

Difference between magnetic flux and magnetic flux density

| Term | Symbol | Unit | Meaning |

|---|---|---|---|

| Magnetic Flux | Φ (Phi) | Weber (Wb) | Total amount of magnetic field passing through a given surface |

| Magnetic Flux Density | B | Tesla (T) | Magnetic flux per unit area; how concentrated the magnetic field is over a surface |

Quick tip: Flux is about the total field over an area, while flux density is about how intense it is at a point.

Leave A Comment