The Fundamentals: What Exactly Is a Temporary Magnet?

A temporary magnet is a type of magnet that only exhibits magnetic properties when exposed to an external magnetic field. Unlike permanent magnets, temporary magnets lose their magnetism once the external field is removed. This behavior makes them ideal for applications where on-demand magnetic control is necessary. Typically, these magnets are made from soft ferromagnetic materials such as soft iron or certain alloys. Their atomic structure allows magnetic domains to align easily under a magnetic field but also return to random alignment without it.

Historically, the study of temporary magnets dates back to early experiments with soft iron and electromagnets in the 19th century. Advances in material science over time have improved their responsiveness and efficiency. Today, innovations include specially engineered soft iron cores and sophisticated alloy compositions that optimize magnetic performance.

Key characteristics of temporary magnets include:

- Low coercivity: They require a minimal external magnetic field to magnetize and demagnetize.

- High permeability: Their ability to channel magnetic flux efficiently.

- Reversibility: Their magnetism can switch on and off quickly and repeatedly.

These traits are crucial because they allow temporary magnets to be both energy-efficient and versatile, powering devices from industrial lifts to everyday electronics. Understanding their fundamentals helps us appreciate the wide range of practical uses where temporary magnets make a real difference.

How Temporary Magnets Work: The Science Behind the Switch

Temporary magnets work by becoming magnetic only when exposed to an external magnetic field. Imagine a bunch of tiny compass needles inside the metal. When you bring a magnet close, these needles line up, creating a magnetic effect. Take away the external magnet, and the needles quickly scatter, losing most of their magnetism. This “on-off” switch is the core of how temporary magnets function.

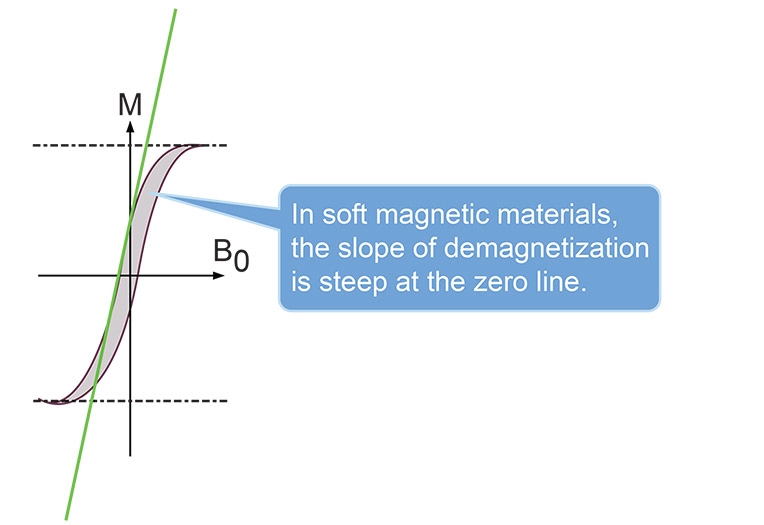

Hysteresis Loops Made Simple

The key to understanding temporary magnets lies in the hysteresis loop, which shows how a material magnetizes and demagnetizes. Think of it like pushing a swing: it takes effort to start swinging and to stop it. Similarly, temporary magnets require a magnetic field (push) to align their domains and lose magnetism quickly once the field is removed. Unlike permanent magnets, they have low coercivity—meaning they don’t hold onto magnetism long after the external field disappears.

What Affects Temporary Magnet Performance?

Several things impact how well a temporary magnet works:

- External Magnetic Field: The stronger and more consistent the field, the better the magnetization.

- Material Composition: Soft iron and certain alloys are common because they easily gain and lose magnetism.

- Temperature: Heat can make it harder for the magnet to maintain alignment, reducing effectiveness.

- Vibration and Movement: Physical disturbances can shake up those tiny domains, weakening the magnet.

Clearing Up Common Misconceptions

- Temporary magnets aren’t weak magnets. They just don’t keep their magnetism without a magnetic field.

- They’re not the same as electromagnets, though electromagnets use this property of temporary magnetism to turn magnetic effects on and off.

- All metals aren’t temporary magnets. Only specific ferromagnetic materials behave this way.

Understanding these basics makes it easier to appreciate how temporary magnets fit into everyday uses and advanced technology alike.

Types of Temporary Magnets: From Simple to Sophisticated

Temporary magnets come in various forms, each suited for different uses and levels of control. Here’s a quick rundown of the common types you’ll find in everyday life and industrial settings.

Soft Iron-Based Magnets and Everyday Examples

Soft iron is the go-to material for many temporary magnets because it magnetizes easily but loses its magnetism just as quickly when the external magnetic field is removed. Think of simple tools like magnetic screwdrivers or clips—these rely on soft iron to provide magnetism only when needed. Soft iron magnets are affordable and effective for low-intensity, short-term magnetic tasks.

Electromagnets: Construction and Variable Strength Control

Electromagnets take temporary magnetism a step further by using electric current to generate magnetic fields. Typically, they feature a coil of wire wrapped around a soft iron core. When current flows, the core magnetizes; when it stops, it demagnetizes. What makes electromagnets valuable is their adjustable strength—you control magnetism simply by tweaking the electric current. This makes them essential for industrial cranes, relays, and even MRI machines.

Other Alloy Variants and Induced Temporary Magnets in Non-Ferrous Metals

Beyond soft iron, some specialized alloys can exhibit temporary magnetism under certain conditions. For example, certain steel mixtures are engineered to have low coercivity, making them good for temporary magnetic roles with improved durability. Additionally, non-ferrous metals can have induced magnetism, though usually weak and short-lived. These alloys and materials find niche roles in sensor technology and specialized electromagnets.

Pros and Cons Comparison Table

| Type | Pros | Cons | Typical Uses |

|---|---|---|---|

| Soft Iron Magnets | Cheap, quick magnetization | Demagnetizes easily, low strength | Hand tools, simple devices |

| Electromagnets | Variable control, high strength | Needs power source, heating issues | Industrial cranes, relays, MRI |

| Alloy Variants | Durable, tailored properties | Costlier, limited availability | Sensors, specialized equipment |

NBAEM’s Specialized Electromagnet Core Materials

At NBAEM, we focus on producing advanced cores that improve electromagnet efficiency—materials with optimized permeability and reduced energy loss. Our high-performance soft magnetic cores are designed to deliver consistent magnetic response even under demanding industrial conditions. This makes NBAEM cores a trusted choice when you need reliable, energy-efficient temporary magnets tailored for the US market.

For a deeper dive into magnetic material properties, check out What Are Magnets Made Of? and the science behind magnetic behavior at What Is BH Curve?.

Temporary vs. Permanent Magnets: A Side-by-Side Comparison

Understanding how temporary magnets stack up against permanent magnets is key when choosing the right type for your project or product. Here’s a quick breakdown focusing on retention, strength, and materials.

| Feature | Temporary Magnets | Permanent Magnets |

|---|---|---|

| Magnetic Retention | Lose magnetism quickly once external field is removed | Maintain magnetism over time without power |

| Magnetic Strength | Generally weaker; depends on external factors (current, field) | Strong and stable based on material type |

| Material Types | Soft iron, silicon steel, ferromagnetic alloys | Neodymium, samarium-cobalt, ferrite |

| Lifespan | Limited; fade due to demagnetization or physical changes | Long-lasting; resist demagnetization |

| Control | Can be switched on/off with power | Fixed magnetic field, not adjustable |

Use-Case Matrix with Decision Flowchart

- Need adjustable magnetism? Go with temporary magnets like electromagnets.

- Require strong, permanent magnetic force? Choose permanent magnets.

- Concerned about energy consumption? Permanent magnets require no power, temporary do.

- Want easy magnet off/on capability? Temporary magnets shine in on-demand magnetic fields.

This simple flowchart helps navigate your choice:

- Is variable strength or on/off control critical?

→ Yes: Temporary magnet

→ No: Permanent magnet - Will the magnet face extreme temperature or harsh environments?

→ Yes: Permanent magnet (some alloys handle environments better)

→ No: Temporary magnet could work

Environmental and Sustainability Impacts

Temporary magnets usually require energy to maintain magnetism, which can impact power consumption and thus environmental footprint—especially in industrial settings. Permanent magnets don’t use energy once magnetized, making them more sustainable in long-term applications.

However, permanent magnets often use rare-earth materials like neodymium, which involve mining challenges and supply concerns. Temporary magnets mostly rely on common ferromagnetic materials like soft iron, which have a smaller environmental burden.

In brief:

- Temporary magnets: Higher energy use but less reliance on rare materials

- Permanent magnets: Zero energy use after magnetization but sourcing issues

For more details on permanent magnets and how they compare, check out What is Permanent Magnet?.

Choosing between temporary and permanent magnets comes down to your specific needs for retention, control, strength, and sustainability. Knowing these differences helps you make smarter, more efficient selections for your applications.

Real-World Applications: Where Temporary Magnets Shine

Temporary magnets play a crucial role in many real-world settings, especially where on-demand magnetic fields are essential.

Industrial Uses

- Cranes: Electromagnets lift heavy steel and scrap metal safely and efficiently, turning the magnetic force on and off as needed.

- MRI Machines: Use powerful temporary magnets to create detailed body scans without permanent magnet materials.

- Automotive Relay Switches: Rely on temporary magnetism to control electrical circuits quickly and reliably.

Consumer Electronics

- Speakers: Use electromagnets to convert electrical signals into sound by moving the speaker cones.

- Hard Drives: Temporary magnets help read and write data by magnetizing specific areas on the disk.

- Magnetic Sensors: Detect position or movement in devices, using temporary magnetism for precise, on-demand responses.

Emerging Technologies

- Renewable Energy Controls: Wind turbines and solar trackers use electromagnets for efficient energy conversion and system regulation.

- Robotics: Temporary magnets provide flexible gripping and movement control, adapting quickly during tasks.

NBAEM’s Role in Advancing Temporary Magnets

NBAEM specializes in high-quality magnetic materials that enhance electromagnet efficiency. Their innovative components help industries achieve stronger, more reliable temporary magnets with improved energy savings.

Partnering with a trusted supplier like NBAEM ensures your temporary magnets perform reliably, saving time and cost in the long run.

Leave A Comment