What Are Neodymium Magnets

Neodymium magnets are a type of rare earth magnet made from an alloy of neodymium (Nd), iron (Fe), and boron (B), commonly referred to as NdFeB. This combination creates the strongest type of permanent magnet available today, offering an exceptional strength-to-size ratio.

These magnets are known for three key performance characteristics:

- High magnetic strength – They produce a very strong magnetic field even in compact sizes.

- High coercivity – They resist demagnetization from external magnetic fields.

- Maximum operating temperature limits – Depending on the grade, most can only operate effectively between 80°C (176°F) and 230°C (446°F) before losing strength.

Because of their power and compactness, neodymium magnets are widely used in applications where both performance and heat resistance matter, such as:

- Electric motors and wind turbines

- Hard disk drives and data storage

- Medical equipment like MRI machines

- Audio devices and speakers

- Industrial holding and lifting tools

For engineers, designers, and hobbyists, understanding temperature tolerance and heat effects is critical, as overheating can lead to permanent loss of magnetism and reduced performance.

The Science Behind Heating Neodymium Magnets

Neodymium magnets get their strength from the alignment of tiny magnetic regions called magnetic domains. These domains stay locked in place under normal conditions, giving the magnet its strong pull. When heat is applied, the extra energy causes the electrons in these domains to move around more, making it harder for them to stay aligned.

Every neodymium magnet has a Curie temperature — usually around 310–400°C (590–752°F) depending on the grade. If the magnet reaches this point, the domains lose all alignment, and the magnet becomes permanently demagnetized. Well before hitting that extreme, heat can still cause a drop in strength.

There are general thermal stability zones to consider:

- Safe range – Most standard grades work fine below 80°C (176°F) without noticeable strength loss.

- Caution zone – Between 80°C and the magnet’s maximum operating temperature, pulling strength will start to dip and may not fully recover.

- Critical zone – Above the rated max temperature, permanent damage and loss of magnetism occur, even if the magnet cools back down.

Knowing these limits is key — especially in applications like motors, sensors, or tools where heat buildup is common.

Effects of Heating on Neodymium Magnets

Heating neodymium magnets has both short-term and long-term effects, depending on how hot they get and for how long.

Temporary effects happen when the magnet is warmed but stays below its maximum operating temperature. You might notice a drop in magnetic pull, but once the magnet cools, most or all of the strength comes back.

Permanent effects occur if the temperature goes beyond the magnet’s critical limit (close to its Curie temperature). At this point, the loss of magnetism is irreversible, and the magnet can’t be restored to its original strength.

Magnetic strength loss grows with heat. Even moderate heating can cause measurable losses:

- Around 5–10% loss if heated near the upper safe range

- Over 20% loss once exceeding rated temperature

- Above the Curie point, nearly total demagnetization

Physical and structural damage is another concern. High heat can lead to:

- Microcracks in the magnet’s surface, making it more brittle

- Faster corrosion, especially if protective coatings are damaged

- Weakening of the magnet’s internal grain structure

Impact on key magnetic properties:

- Coercivity (resistance to demagnetization) typically drops with heat, making magnets easier to weaken

- Remanence (residual magnet strength) decreases steadily at elevated temperatures

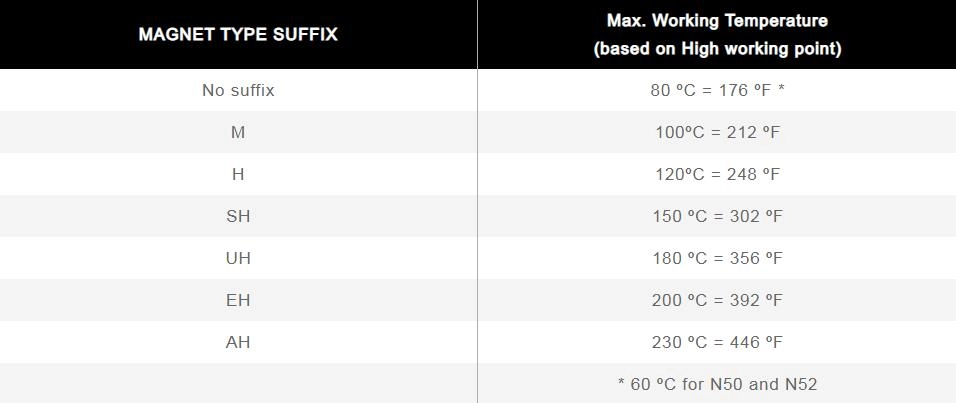

Maximum Operating Temperature and Thermal Limits

Neodymium magnets don’t all handle heat the same way. Each grade has its own maximum operating temperature, which is the point where it starts losing magnetic strength. For example:

| Grade | Max Operating Temp (°F) | Max Operating Temp (°C) |

|---|---|---|

| N35 | ~176°F | ~80°C |

| N42 | ~176°F | ~80°C |

| N52 | ~140°F | ~60°C |

| High Temp Grades (e.g., N35EH) | 392°F | 200°C |

Manufacturers will usually give a safe working range that’s a bit below the absolute limit to keep magnets from degrading over time. That’s because heat damage can be gradual—staying just under the max rating for long periods can still cause magnetic loss.

Heat treatment during manufacturing can improve a magnet’s thermal endurance, especially for industrial applications where higher operating temps are common. Protective coatings like nickel, epoxy, or specialized heat-resistant platings also help. While coatings won’t stop demagnetization, they prevent surface damage, corrosion, and microcracks that heat can accelerate.

Practical Implications for Industrial and Consumer Use

Heating can have a big impact on how neodymium magnets perform in real-world applications. In motors, generators, and other electronics, excess heat can cause magnets to lose part of their strength, which may reduce torque, lower efficiency, or cause the device to stop working altogether. Even a short time over their rated maximum operating temperature can trigger partial or permanent demagnetization.

For industrial systems that run under heavy loads or in hot environments—like wind turbines, EV motors, or CNC machinery—ignoring neodymium magnet temperature tolerance can lead to costly breakdowns. In consumer products, such as speakers or magnetic mounts, heat from nearby components can slowly degrade performance over time.

Risks when thermal effects are ignored:

- Reduced magnetic strength and performance loss

- Overheating-related device failures

- Safety hazards from mechanical issues or electrical overload

- Shortened lifespan of the equipment

Best practices for choosing magnets for hot environments:

- Match the magnet grade to the expected operating temperature

- Use heat-resistant coatings or encapsulation to slow down thermal degradation and corrosion

- Allow for a thermal safety margin above expected maximum temperatures

- Position magnets away from known heat sources in the design stage

- Consider high-temperature grades or alternative magnet types (like SmCo) for extreme conditions

Keeping magnets within their safe temperature range ensures stable performance and avoids premature equipment failure, whether you’re running an industrial plant or building high-performance electronics at home.

Mitigating Heat Effects on Neodymium Magnets

If your application runs hot, there are ways to protect neodymium magnets from heat damage. Small changes in design, materials, and storage can make a big difference.

Improve Heat Tolerance

- Choose heat-resistant grades – Some NdFeB magnets are engineered for higher max operating temperatures (up to 230°F–300°F) compared to standard grades.

- Use special alloys – Adding elements like dysprosium or terbium can boost coercivity and thermal resistance.

- Apply protective coatings – Epoxy, nickel-copper-nickel, or other high-temp coatings can reduce oxidation and surface breakdown at elevated temperatures.

- Optimize assembly design – Position magnets away from direct heat sources or add thermal barriers in the assembly.

Storage and Handling Tips

- Keep magnets in a temperature-controlled space, ideally under 140°F.

- Avoid storing them near engines, heaters, or other heat-generating equipment.

- Use padded, non-metal containers to prevent chipping from thermal expansion stress.

When to Consider Alternatives

If the operating environment regularly exceeds a magnet’s temperature limit, it may be better to:

- Switch to Samarium Cobalt magnets – They handle higher temperatures with less demagnetization risk.

- Use ferrite magnets for lower-cost, moderate-strength applications in high heat.

- Combine magnets with heat-dissipating carriers or mounts to spread out thermal load.

Selecting the right grade and protective strategies up front will keep magnetic performance stable and equipment running longer.

NBAEM’s Expertise Supplying High Performance Neodymium Magnets

At NBAEM, we supply high-performance neodymium magnets designed to deliver consistent strength and reliability, even when operating near their maximum temperature limits. We know that in the U.S. market, magnets are often used in demanding applications—industrial motors, generators, EV components, and specialized electronics—where heat resistance can make or break performance.

Our product lineup covers a wide range of grades and temperature tolerances, from standard N35 types to high-temp options capable of withstanding up to 200°C without significant loss of magnetism. If you need a custom size, coating, or alloy blend for better thermal stability, we can manufacture to your exact specs.

All our magnets go through strict quality testing, including thermal endurance trials, to ensure they meet manufacturer temperature ratings and maintain magnetic strength over time. We also offer guidance on selecting the right grade for your environment to prevent heat-related demagnetization and reduce maintenance risks.

If you’re looking for magnets that can handle both power and heat, our engineers can help match you with the optimal solution. Learn more about material performance in our guide to rare earth magnets or reach out directly for a free consultation on your thermal application needs.

Leave A Comment