Are you struggling to determine exactly what magnet materials are best for Halbach arrays?

Get this wrong, and your high-tech assembly could suffer from demagnetization, thermal instability, or poor efficiency.

As a custom magnet expert, I know that Halbach configurations demand more than just standard magnets—they require materials with exceptional intrinsic coercivity and magnetic remanence to withstand intense opposing fields.

In this guide, you’ll discover why Sintered Neodymium (NdFeB) and Samarium Cobalt (SmCo) are the industry standards, and how to select the perfect grade for your specific temperature and performance needs.

Let’s get to the core of the matter.

Why Halbach Arrays Demand Exceptional Magnet Materials

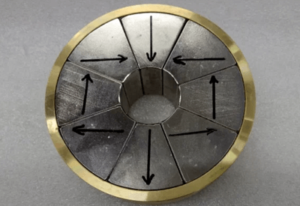

When we engineer a Halbach array, we aren’t simply stacking magnets; we are forcing magnetic fields into a conflict that physics naturally resists. The unique geometry of a Halbach cylinder ring or linear Halbach array relies on rotating the magnetization direction by 90° between segments. While this successfully cancels the field on one side and amplifies it on the other, it creates a hostile environment for the material itself.

Understanding Internal Demagnetizing Fields

In standard magnetic assemblies, poles usually align to minimize resistance. In a Halbach configuration, we force magnets to sit in direct opposition to the fields of their neighbors. This generates severe Halbach array demagnetization stress. If the material selected cannot withstand this internal pressure, the magnets will effectively “attack” each other, leading to a permanent loss of magnetic strength.

The Role of Remanence (Br) and Intrinsic Coercivity (Hci)

To survive this magnetic conflict and deliver the 1.4x to 2x performance gain we expect from NBAEM assemblies, we focus on two critical metrics:

- Magnetic Remanence (Br): This measures the raw strength of the magnetic field. High Br is essential for maximizing the one-sided flux concentration effect.

- Intrinsic Coercivity (Hci): This is the magnet’s ability to resist demagnetization. In Halbach arrays, Intrinsic coercivity Hci is often more important than raw strength. Without high Hci, the opposing fields within the array will permanently deplete the magnet’s energy.

Why Standard Magnets Fail in This Geometry

Standard consumer-grade magnets often lack the specific high coercivity required for these complex assemblies. When placed into a Halbach pattern, low-grade materials suffer from irreversible magnetic loss almost immediately. To ensure stability and longevity, we strictly utilize high-grade Rare earth permanent magnets—specifically engineered to maintain their magnetic orientation despite the intense opposing forces inherent to the design.

Sintered Neodymium (NdFeB): The Powerhouse Choice

When the goal is maximizing magnetic flux density in a compact footprint, Sintered Neodymium (NdFeB) is the undisputed leader. In our 14+ years of engineering custom assemblies, we have found that a Neodymium Halbach array offers the highest performance-to-weight ratio available. These rare earth permanent magnets possess the extreme Remanence (Br) required to sustain the complex field interactions of a Halbach configuration, delivering the signature one-sided flux concentration that is 1.4x to 2x stronger than conventional layouts.

Why NdFeB Dominates High-Performance Arrays

The geometry of a Halbach array forces magnetic fields to oppose each other internally. Weak materials will succumb to this stress and demagnetize. Sintered NdFeB resists this demagnetization better than almost any other material at room temperature, making it the primary choice for EV motors, robotics, and high-tech industrial machinery.

Recommended Grades for Optimization

Selecting the right grade is critical for balancing cost and field strength. We typically recommend specific Sintered NdFeB grades N52 and others based on the application:

- N50 – N54: The highest energy product (up to 52 MGOe). Best for static holding applications or where size constraints are extreme.

- N42 – N45: The industry workhorse. Offers a reliable balance of high strength and cost-efficiency for general linear Halbach arrays.

- N48H / N42SH: High-coercivity grades designed for dynamic applications like rotors. These resist demagnetization even when the assembly heats up during operation.

To ensure your array performs as predicted, verifying the quality of Neodymium magnets is essential, as inconsistencies in grain structure can disrupt the precise field uniformity required for Halbach setups.

Managing Temperature Limits and Coatings

While NdFeB is powerful, it has two main vulnerabilities: heat and corrosion. Standard N-grades begin to lose magnetic output above 80°C. For applications involving friction or electrical resistance (like motor stators), we utilize high-temperature series (M, H, SH, UH, EH) that operate reliably up to 230°C.

Furthermore, sintered NdFeB contains iron, making it prone to rust. We apply specialized surface treatments to protect the assembly:

- Ni-Cu-Ni (Nickel): The standard durable coating for most environments.

- Zinc: Better corrosion resistance in certain industrial settings.

- Epoxy: Ideal if the magnets are exposed to moisture or salt spray.

Samarium Cobalt (SmCo): The Heat Survivor

Samarium Cobalt Halbach array

When the operating environment gets too hot for Neodymium, we turn to Samarium Cobalt (SmCo). A Samarium Cobalt Halbach array is the industry standard for applications demanding unwavering performance under thermal stress. While NdFeB loses strength rapidly above 200°C, our SmCo grades maintain magnetic flux density and resist demagnetization at temperatures as high as 300°C to 350°C. This makes them indispensable for high-speed aerospace rotors and industrial motors where heat generation is unavoidable.

SmCo5 vs Sm2Co17: Choosing the Right Grade

Selecting the specific alloy composition is critical for optimizing your assembly.

- SmCo5 (1:5 Series): Offers excellent coercivity but slightly lower energy products (typically 16-25 MGOe).

- Sm2Co17 (2:17 Series): The preferred choice for most modern high-performance arrays. It delivers higher magnetic strength (up to 32 MGOe) and superior temperature resistance compared to the 1:5 series.

Performance in Corrosive Environments

One of the biggest advantages of SmCo is its natural resistance to oxidation. Unlike Neodymium, which requires heavy plating, SmCo is inherently stable.

Alternative Materials: When to Use Them

While sintered rare earth magnets dominate high-performance applications, specific engineering constraints sometimes point us toward alternative options from our comprehensive range of magnet materials.

Bonded NdFeB for Complex Shapes

When a design requires intricate geometries that sintered blocks cannot achieve, Bonded NdFeB is the solution. Since these are created by mixing magnetic powder with a polymer binder, we can injection mold them into complex, net-shape components. This is particularly useful for circular Halbach arrays in small precision motors where the assembly of individual glued segments is impractical. Although the energy product is lower than sintered grades, the ability to create multi-pole magnetization patterns directly on a single ring often outweighs the raw strength deficit in miniaturized devices.

Why Ferrite and Alnico Are Rarely Suitable

We generally advise against using Ferrite (Ceramic) or Alnico for Halbach configurations unless specific low-cost or high-temperature variables are at play.

- Ferrite: With a low energy product (roughly 3.4–4.5 MGOe), Ferrite magnets struggle to generate the strong flux concentration that defines a Halbach array. The performance gain usually doesn’t justify the complex assembly effort.

- Alnico: While Alnico has high remanence, its low coercivity makes it susceptible to demagnetization. In a Halbach array, magnets are forced into opposition; Alnico often cannot withstand these internal opposing fields without losing its charge.

Cost vs. Performance Trade-offs

Choosing the right material is a balance of magnetic flux density against budget. Sintered Neodymium offers the best performance-per-dollar for high-strength fields, whereas Ferrite offers the lowest raw material cost but results in a significantly bulkier and weaker system. For most of our clients needing compact, high-efficiency arrays, the premium for rare earth materials is a necessary investment to eliminate heavy iron backplates and maximize the power-to-weight ratio.

Head-to-Head: NdFeB vs. SmCo

When we engineer high-performance magnet assemblies, the choice for Halbach configurations almost always narrows down to two contenders: Sintered Neodymium (NdFeB) and Samarium Cobalt (SmCo). While both are rare earth permanent magnets capable of sustaining the complex magnetic fields required for a Halbach array, they serve different engineering priorities.

Comparison of Maximum Energy Product (MGOe)

For applications where size and weight are the primary constraints, NdFeB vs SmCo Halbach comparisons heavily favor Neodymium.

- NdFeB: This is the undisputed king of strength. Our N54 grades reach an energy product of up to 52 MGOe. This allows us to build compact arrays that deliver massive flux density (amplified 1.4x to 2x in our Halbach designs).

- SmCo: While powerful, Samarium Cobalt tops out around 32 MGOe. To achieve the same magnetic field strength as a Neodymium array, a SmCo array would need to be physically larger.

Cost Analysis and Demagnetization Resistance

The magnet energy product MGOe isn’t the only factor. Halbach array demagnetization risks increase significantly with heat.

- Thermal Stability: SmCo is the “heat survivor.” It maintains performance up to 350°C with minimal flux loss. NdFeB is more sensitive; standard grades lose strength rapidly above 80°C, though our specialized high-temp grades can handle up to 230°C.

- Budget: NdFeB generally offers a better price-to-performance ratio. SmCo is more expensive due to raw material costs (Cobalt) and processing difficulty, making it a premium choice reserved for extreme environments.

Quick Specs: Material Selection Guide

| Feature | Sintered Neodymium (NdFeB) | Samarium Cobalt (SmCo) |

|---|---|---|

| Magnetic Strength | Very High (33–52 MGOe) | High (16–32 MGOe) |

| Max Operating Temp | 80°C – 230°C (Grade dependent) | 300°C – 350°C |

| Corrosion Resistance | Low (Requires Ni/Zn coating) | Excellent (No coating needed) |

| Demagnetization Resistance | High (High Hci grades available) | Very High (Extremely stable) |

| Best For | EV Motors, Robotics, Consumer Tech | Aerospace, Marine, High-Heat Industrial |

Critical Selection Criteria for Your Project

Selecting the right material for a custom Halbach assembly isn’t just about picking the strongest magnet on the datasheet. We approach every project by balancing three non-negotiable factors to ensure the array performs reliably over its lifespan.

Defining Operating Temperature Ranges

Temperature stability is the first question we ask. Standard Neodymium magnets lose performance quickly if the heat rises above their grade rating.

- Standard Applications: For environments under 80°C, standard N-grade NdFeB offers the best power-to-weight ratio.

- High-Heat Applications: If your motor or sensor assembly operates between 150°C and 230°C, we upgrade to UH or EH series Neodymium.

- Extreme Heat: Once you cross 300°C, we switch entirely to Samarium Cobalt (SmCo), which maintains stability up to 350°C without irreversible demagnetization.

Assessing Environmental Factors

The physical environment dictates the longevity of the array. Neodymium is iron-rich and prone to corrosion in humid conditions, requiring robust coatings like Nickel-Copper-Nickel, Zinc, or Epoxy. For vacuum environments or marine applications where coatings might fail or outgas, SmCo is superior because it offers natural corrosion resistance without needing extra protection.

Required Magnetic Field Strength and Uniformity

A Halbach array is designed to amplify magnetic flux on one side while canceling it on the other. To achieve the 1.4x to 2x flux density gain we typically see, the uniformity of the magnetic properties is critical.

- Maximum Strength: If the goal is the highest possible holding force or torque in a compact space, we utilize high-grade N52 or N54 NdFeB.

- Precision Fields: For sensors or particle accelerators requiring extremely stable magnetic flux and surface gauss, we prioritize materials with consistent intrinsic coercivity (Hci) to prevent localized demagnetization within the array structure.

Real-World Applications and Material Matches

Selecting the right magnet composition isn’t just about raw strength; it is about matching the Halbach array characteristics to the specific demands of the operating environment. We engineer custom magnetic assemblies where the material choice dictates the longevity and efficiency of the final system.

Electric Vehicle Motors and Drones (NdFeB)

In the EV and drone sectors, power-to-weight ratio is everything. A Neodymium Halbach array is the standard choice here because it offers the highest magnetic flux density available—up to 52 MGOe. By utilizing a Halbach configuration, we can focus the magnetic field entirely on the working face, often eliminating the need for heavy steel backplates. This reduces the overall motor weight by up to 20% while increasing torque.

- Material: Sintered NdFeB (Grades N45SH, N52).

- Benefit: Maximum torque density and lightweight design.

- Use Case: High-speed rotors and industrial magnet applications requiring compact efficiency.

Aerospace and Defense Systems (SmCo)

When equipment faces extreme thermal stress, standard magnets fail. For aerospace actuators and defense systems, we rely on Samarium Cobalt Halbach assemblies. These materials maintain magnetic stability at temperatures ranging from 300°C to 350°C. Unlike Neodymium, SmCo offers natural corrosion resistance, making it essential for exposed or vacuum environments where protective coatings might degrade.

Medical Imaging and Magnetic Bearings

Precision is the priority for medical devices. Linear Halbach arrays are frequently used in magnetic bearings and particle accelerators to create strong, uniform, and self-shielding fields.

- Magnetic Bearings: Use NdFeB for high load capacity or SmCo for sterilization-proof stability.

- Imaging: Requires the precise 90° orientation changes our engineering team delivers to ensure field homogeneity.

Matching the material to the application ensures you get the 1.4x to 2x performance gain that a properly designed Halbach array promises.

FAQs About Halbach Array Materials

Can I use ceramic magnets for a Halbach array?

Yes, you can use ceramic (ferrite) magnets, but they are generally reserved for cost-sensitive applications where weight and size are not critical constraints. While ferrite offers excellent resistance to corrosion and demagnetization, its Maximum Energy Product (MGOe) is significantly lower (typically 3.4–4.5 MGOe) compared to rare earth options.

If your project requires a compact design with high holding force, we usually recommend upgrading materials. You can see the performance gap in our detailed breakdown of ferrite magnet vs neodymium, which highlights why rare earth materials are the standard for high-performance linear Halbach arrays.

What is the strongest magnet grade for Halbach?

For maximum magnetic flux density, Sintered Neodymium (NdFeB) is the superior choice. At NBAEM, we manufacture grades up to N52 and N54, which currently offer the highest magnetic energy available commercially.

Using these premium grades in a neodymium Halbach array allows us to achieve a flux concentration that is 1.4x to 2x higher than conventional magnet assemblies. This is critical for applications like high-speed rotors or magnetic bearings where you need the strongest possible field in the smallest possible package.

How does heat affect Halbach array performance?

Temperature management is critical because the complex opposing fields in a Halbach configuration create high internal stress. If the operating temperature exceeds the magnet’s rating, you risk irreversible Halbach array demagnetization.

- Standard NdFeB: Loses strength rapidly above 80°C (unless specialized high-temp grades like UH or EH are used).

- Samarium Cobalt (SmCo): Maintains stability up to 300°C–350°C.

For environments involving extreme heat, such as aerospace turbines or industrial motors, we prioritize Halbach array temperature resistance by specifying SmCo over NdFeB to ensure the assembly retains its magnetic properties over time.

Leave A Comment