The Science Behind Temporary Magnets: Why They Matter

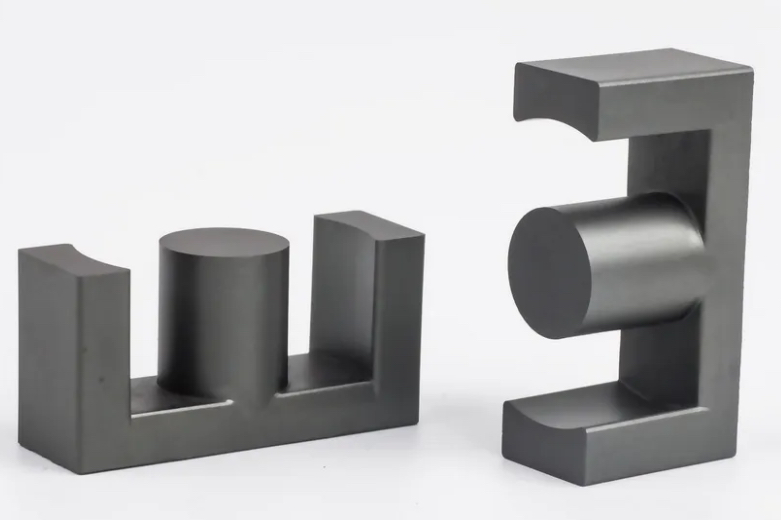

soft ferrite

Have you ever wondered how temporary magnets work and why they are so important across industries? Unlike permanent magnets, temporary magnets—commonly known as electromagnets—only exhibit magnetism when an electric current passes through them. This controllable magnetic field makes them incredibly versatile for countless applications.

At the core of temporary magnets are soft magnetic materials such as soft iron, nickel alloys, and high-permeability silicon steel. These materials easily gain and lose magnetism, allowing the magnet to turn on and off with the flow of electricity. This contrasts sharply with permanent magnets, which maintain a constant magnetic field.

Advantages Over Permanent Magnets

Temporary magnets offer several key benefits:

- Controllability: You can easily switch their magnetic effect on or off, adapting to different needs.

- Adjustable Strength: By varying the electric current, the magnetic force can be fine-tuned for specific tasks.

- Cost-Efficiency: Often more economical as they don’t require rare materials and can be reused without degradation.

- Safety: When powered down, they lose their magnetism, reducing risks in sensitive environments.

Common Materials Used

The effectiveness of temporary magnets depends heavily on their core materials:

- Soft Iron: Highly responsive, ideal for quick magnetization and demagnetization.

- Nickel Alloys: Provide durability and enhanced magnetic properties.

- Silicon Steel: Known for excellent permeability and energy efficiency in electromagnet cores.

Understanding these basics sets the stage for exploring where temporary magnets shine in real-world applications—from industrial machinery to consumer electronics.

Industrial Powerhouses: Heavy-Duty Applications

Temporary magnets, especially electromagnets, are workhorses in heavy industries. One of the most common uses is in recycling and material sorting—electromagnets mounted on cranes quickly separate ferrous metals from waste streams, making the process efficient and cost-effective.

In manufacturing, magnetic chucks hold metal parts firmly during precision machining and assembly, ensuring accuracy without damaging sensitive materials. These temporary magnets provide strong but controllable force, which is critical in high-volume production lines.

Material handling also benefits from temporary magnet tech. Overhead lifters and conveyor systems use electromagnets to safely move bulky steel parts and components around factories and warehouses without needing mechanical clamps or hooks, streamlining workflow and reducing downtime.

Companies like NBAEM supply custom electromagnet coils designed to meet the high-demand needs of industrial customers. Their coils are built for durability, adjustable strength, and reliable performance in the toughest environments — perfect for industries looking for dependable temporary magnet solutions that can handle heavy lifting and sorting all day long.

For more info on industrial magnet applications, check out NBAEM’s resources on magnets used in industrial settings.

Electronics and Consumer Tech: Everyday Essentials

Temporary magnets play a big role in the electronics and consumer tech we use every day. Inside electric motors and generators found in appliances and power tools, these magnets help control variable speeds efficiently. This adjustability makes devices run smoother and last longer.

In audio equipment, temporary magnets contribute to clear, high-quality sound by managing sound reproduction precisely. You’ll also find them in communication devices like telephones and smartphones, where they support components that need reliable, on-demand magnetic fields.

Emerging tech relies heavily on temporary magnets too. MRI machines use strong but controlled magnetic fields for detailed imaging. Smart home devices depend on electromagnetic relays for quick switching, and IoT gadgets leverage compact temporary magnets for seamless integration.

NBAEM offers high-grade soft iron cores designed for these compact and efficient setups, making them a trusted choice for manufacturers aiming to balance performance with size. For more details on how temporary magnets work, check out what is temporary magnet.

Household and Educational Uses: From Garage to Classroom

Temporary magnets show up in lots of everyday spots around the house and in classrooms. Simple tools like paperclip catchers, nail retrievers, and DIY electromagnets are common for small jobs and fun projects. These magnets make it easy to pick up metal bits without hassle.

In many homes, temporary magnets power doorbells, circuit breakers, and electromagnetic relays, helping devices work safely and efficiently. These appliances rely on the controllable, on-demand magnetism that temporary magnets provide to operate only when needed.

For students and hobbyists, temporary magnets are perfect for hands-on experiments that explain how magnetism works. DIY kits come with safety tips to keep learning fun and trouble-free. NBAEM offers affordable starter kits designed specifically for educators, featuring high-quality, durable components that perform reliably in classroom settings.

If you’re looking to explore magnetism at home or in school, these simple, safe tools and sets make a great starting point.

Specialized Applications: Niche Innovations

Temporary magnets play a big role in some pretty specialized fields. In medical and scientific settings, they’re used in particle accelerators and non-invasive therapies where controlled magnetic fields are a must. In the automotive world, electromagnets help with starters, windshield wipers, and ABS systems by providing on-demand magnetism that’s both reliable and efficient.

Over in defense and aerospace, lightweight temporary magnets are prized for guidance systems and fail-safe performance, where every ounce and every action counts. Looking ahead, these magnets are expected to be crucial in renewable energy controls and the growing automation market, keeping industries efficient while supporting clean technology and smart processes.

Choosing the Right Temporary Magnet: Practical Guide

Picking the right temporary magnet mostly depends on where and how you plan to use it. Here are the key factors to keep in mind:

- Load Capacity: Match the magnet’s strength to the weight or size of the object you need to hold or move.

- Response Time: For applications like relays or switches, you’ll want magnets that activate and deactivate quickly.

- Environmental Resistance: Consider temperature, moisture, or corrosion where the magnet will work.

- Integration: Ensure the magnet fits well with your existing systems or designs, especially in electronics or machinery.

Common Pitfalls to Avoid

- Demagnetization: Avoid magnets made with materials that lose strength quickly after removing power.

- Coercivity Issues: Low coercivity can cause magnets to lose their magnetic properties from stray fields or heat.

Temporary vs Permanent Magnets: Quick Comparison

| Feature | Temporary Magnet | Permanent Magnet |

|---|---|---|

| Strength | Adjustable, depends on current | Fixed strength |

| Cost | Usually lower upfront | Higher upfront cost |

| Use Cases | On-demand lifting, motors, relays | Sensors, holding, compasses |

| Lifespan | Long with proper care | Permanent but can weaken over years |

By focusing on your specific application and environment, you can pick the best temporary magnet that delivers reliable performance without overspending.

Leave A Comment