Why are segment magnets so efficient? If you’ve ever wondered what sets segmented magnets apart in high-performance applications—from electric vehicles to wind turbines—this is where the real magic happens. Segment magnets, especially neodymium arc types, slash energy losses by tackling pesky eddy currents, concentrate magnetic fields for stronger output, and deliver custom-fit designs that boost efficiency like never before. In a world chasing every percentage point of motor performance, understanding why segment magnets dominate efficiency isn’t just smart—it’s essential. Stick around, and you’ll discover how smart segmentation turns raw magnetic power into precision, reliability, and next-level energy savings.

segement magnets

The Science Behind Segment Magnets Efficiency Edge

Segment magnets owe their efficiency primarily to how they manage magnetic flux and minimize energy losses. At the core, these magnets are designed as segmented neodymium magnets, which means the magnet material is divided into precise arc-shaped sections. This segmentation allows for better flux concentration and uniformity—key factors that enhance magnetic performance.

Flux concentration and uniformity refer to how evenly and effectively the magnetic field is distributed. In traditional block magnets, flux can leak or become uneven, reducing efficiency. Segmented arc magnets align better with curved surfaces, like those in electric motors, leading to a stronger, more consistent magnetic field that boosts torque and reduces energy waste.

Another critical element is battling eddy currents, a common hidden efficiency killer. Eddy currents are loops of electric current induced within the magnet or surrounding metal parts, which generate heat and waste energy. Segmentation breaks the magnetic material into smaller, isolated sections, significantly reducing these currents and their related losses.

Finally, segment magnets are engineered to resist thermal and demagnetization effects. High temperatures and opposing magnetic fields can weaken magnets over time. The segmented design, combined with high-quality NdFeB (neodymium iron boron) materials, improves heat tolerance and maintains magnetic strength, contributing to long-term reliability and efficiency.

In short, the science behind segment magnets centers on optimized magnetic flux, minimized eddy current loss, and enhanced durability—making them a standout choice for permanent magnet motor efficiency and other high-performance applications.

Key Advantages of Segment Magnets Over Traditional Designs

Segmented magnets offer several clear benefits compared to traditional one-piece magnets. Here’s why they stand out:

-

Better Flux Concentration

Segment magnets, especially segmented neodymium magnets, focus the magnetic field more evenly. This improves magnetic field uniformity, which means the motor or device runs smoother and more efficiently.

-

Reduced Eddy Current Losses

Traditional magnets can create eddy currents that waste energy and cause heat. Segmenting the magnet breaks up these loops, cutting down on eddy current reduction in motors and boosting overall efficiency.

-

Improved Thermal Resistance

Segment magnets handle heat better. This is important because excess heat can demagnetize or damage magnets. Segmentation helps keep temperatures lower, extending magnet life and maintaining performance.

-

Higher Torque Density

Thanks to optimized shapes and placement, segmented magnets contribute to permanent magnet motor efficiency by producing higher torque density. This means smaller, lighter motors can pack more power—something valued in EV rotor magnet design and other compact applications.

-

Customizable Designs

Segment magnets allow for tailored shapes, like arc magnet flux concentration in custom arc segment suppliers, fitting perfectly into advanced motor designs. This flexibility is key for industries demanding precision and efficiency.

In short, segmented magnets combine efficiency, durability, and adaptability in a way traditional magnets struggle to match. This makes them a preferred choice for high-performance motors and energy systems across the U.S. market.

Real-World Applications Where Efficiency Shines

Segment magnets really show their strength in practical use, especially where efficiency is non-negotiable.

Electric Motors and Generators

In electric motors and generators, segmented neodymium magnets play a critical role by improving magnetic field uniformity and reducing eddy current losses. This leads to higher torque density and better overall performance. The precise flux concentration from arc-shaped segments means motors run smoother and cooler—key for extending life and saving energy. This is why permanent magnet motor efficiency often hinges on the quality and design of these segmented magnets.

Renewable Energy and Beyond

Wind turbines and solar power systems benefit from these magnets too. Segmented NdFeB magnets contribute to reliable, powerful performance in generators, ensuring consistent energy output even under varying conditions. If you’re interested in how magnets fuel renewable energy, check out how they’re optimized for such applications. Their ability to resist demagnetization and thermal stress makes them a favorite in harsh, real-world environments.

Emerging Trends EVs and High-Speed Rail

The rise of electric vehicles (EVs) and high-speed rail pushes demand for magnets that deliver top-notch efficiency and durability. EV rotor magnet designs often rely on segmented neodymium magnets to reduce losses and deliver high torque from compact motor sizes, helping improve driving range and power. High-speed rail systems also take advantage of these magnets for smooth, energy-efficient operation at high speeds.

In all these fields, segment magnets cut down on wasted energy and boost performance—making them a smart choice for the future of mobility and green tech. For more about how magnets shape motor technology, visit our detailed guide on magnets used in motor applications.

Design and Manufacturing Insights for Optimal Efficiency

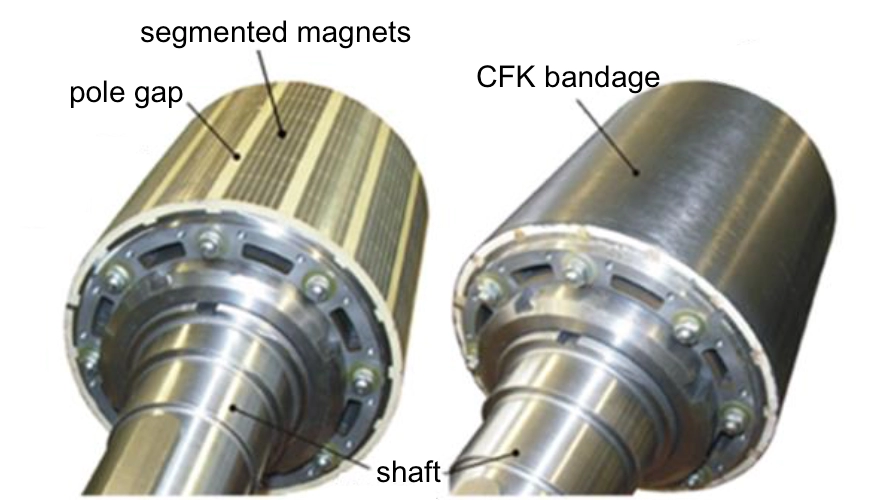

When it comes to making segment magnets efficient, the design and manufacturing process plays a big role. Two main segmentation techniques are commonly used: continuous and intermittent segmentation.

- Continuous segmentation means the magnet is divided into smooth, consistent arc segments. This helps maintain uniform magnetic flux and reduces losses caused by uneven fields.

- Intermittent segmentation breaks the magnet into separate pieces with small gaps. This method is useful for preventing eddy currents, which can drag down permanent magnet motor efficiency, especially in high-speed applications.

Choosing the right technique depends on the specific motor or generator design and the balance needed between performance and cost.

Material choice also matters, and NdFeB (neodymium-iron-boron) magnets dominate here. Why? NdFeB offers the highest magnetic strength and excellent resistance to demagnetization compared to other rare earth magnets. Its ability to maintain strong magnetic fields in a smaller size helps improve torque density and reduce weight—both crucial in industries like EV rotor magnet design.

That said, manufacturers must watch out for common pitfalls:

- Magnet cracking during segmentation is a risk, especially with brittle NdFeB materials. Precise cutting and handling are critical.

- Flux leakage at segment joints can drop efficiency, so tight tolerances and proper adhesive bonding matter.

- Thermal management challenges arise because magnets can lose strength if they overheat, so selecting proper coatings and integrating cooling solutions helps.

Addressing these challenges effectively leads to optimal efficiency and durability in segmented neodymium magnets. For more detailed insights on choosing the right magnet material and managing temperature impacts, check out this guide to rare earth magnets.

NBAEM Your Partner in HighEfficiency Segment Magnets Solutions

When it comes to sourcing segmented neodymium magnets that deliver premium performance and efficiency, NBAEM stands out as a trusted partner. With a strong focus on advanced NdFeB segmentation techniques and quality control, NBAEM ensures your motors and devices benefit from magnets that reduce eddy current losses and boost magnetic field uniformity.

Here’s why NBAEM is a go-to supplier for the U.S. market:

- Tailored Solutions – Custom arc segment suppliers that adapt magnet sizes and shapes to fit specific applications, from EV rotor magnet design to renewable energy systems.

- Material Expertise – Specializing in high-grade NdFeB materials engineered for maximum torque density and thermal stability, helping you avoid demagnetization even in demanding settings.

- Manufacturing Precision – Strict quality checks to maintain flux concentration and minimize efficiency killers like eddy currents.

- Support for Innovation – NBAEM stays aligned with emerging trends including high-speed rail and high-performance electric motors.

If you want to boost permanent magnet motor efficiency with reliable segment magnets, NBAEM offers the experience and technical know-how to make it happen. Learn more about how magnets affect performance at NBAEM’s heating effects page and explore applications with NBAEM’s motor magnet resources. Together, we can help you achieve the next level of magnetic efficiency.

Leave A Comment