Unmatched Corrosion Resistance for Tough Environments

One of the biggest reasons to choose rubber coated magnets over bare NdFeB is their exceptional corrosion resistance. Bare neodymium magnets start to degrade quickly when exposed to moisture, especially in salty or humid conditions. In contrast, rubber coated magnets withstand harsh environments far better.

- 1000-hour salt spray test: While bare NdFeB magnets show visible rust and performance loss within a few hundred hours, rubber coated magnets remain fully intact with no corrosion signs after 1000 hours of continuous salt spray exposure.

- IP67/IP68 waterproof ratings: Rubber coatings provide robust waterproofing essential for marine and outdoor applications, including full submersion. This level of protection meets industrial standards, ensuring magnets keep their properties under water, rain, and high humidity.

- Real-world case: An NBAEM client used rubber coated magnets to mount sensors on offshore wind turbines. These sensors operate in aggressive marine conditions with constant saltwater spray, severe winds, and mechanical stress. Thanks to the rubber coating, the sensors stayed firmly in place without rust or degradation for over 3 years.

Rubber coated magnets offer reliable protection where bare magnets simply cannot last, making them the preferred choice for marine, outdoor, and coastal applications requiring long-term durability and stable magnetic performance.

Superior Surface Protection & Grip

Rubber coated magnets stand out for their excellent surface protection. The TPE (thermoplastic elastomer) coating is soft and non-marring, so it won’t scratch or damage painted metals or delicate surfaces—unlike bare or harder plastic-coated magnets. This makes them ideal for sensitive applications where appearance and surface integrity matter.

On top of protection, the rubber coating offers a 30–50% higher friction coefficient compared to standard plastic coatings. That extra grip helps the magnet hold steady on smooth or sloped surfaces, reducing unwanted slipping or sliding.

You’ll often find these rubber coated neodymium magnets used in automotive assembly jigs, where precision and surface care are essential, and in retail display hooks that need to firmly grip without marking premium displays. Their combination of gentle touch and strong hold makes them a top choice in these industries.

Core Advantage 3: Impact & Vibration Dampening

Rubber coated magnets excel at absorbing shocks and vibrations, which is a major plus in dynamic environments. This impact dampening prevents magnet fractures that commonly occur with bare neodymium magnets when exposed to constant movement or drops. For example, conveyor systems and robotic grippers benefit significantly from rubber overmolded NdFeB magnets because the rubber layer reduces noise caused by metal-on-metal contact.

In rigorous testing, rubber coated magnets maintained strong pull force even after 10,000 drop cycles—proving their durability in high-impact settings. This reliable retention of strength means fewer replacements and less downtime, especially in automation or industrial applications where vibrations and sudden impacts are frequent.

If your setup involves moving parts or heavy machinery, choosing rubber coated neodymium magnets offers lasting protection and performance that plastic or bare magnets can’t match.

Comparative Analysis: Rubber vs. Plastic vs. Bare Magnets

When choosing between rubber coated neodymium magnets, plastic-coated, or bare magnets, it’s important to weigh key factors like pull force, cost, lifespan, and temperature range.

| Feature | Rubber Coated | Plastic Coated | Bare Magnets |

|---|---|---|---|

| Pull Force | High (30–50% better grip) | Moderate | Highest (no coating barrier) |

| Cost | Moderate (mid-range pricing) | Lowest | Lowest upfront, but costly long-term |

| Lifespan | Long (excellent corrosion resistance) | Moderate | Short (prone to rust and chipping) |

| Temperature Range | -40°C to 120°C | -20°C to 80°C | -40°C to 150°C |

Cost-Per-Year ROI: In high-humidity or marine environments, rubber coated magnets offer superior value despite a slightly higher initial cost. Their unmatched corrosion resistance and durability lower replacement frequency, bringing down the overall cost per year compared to plastic or bare magnets.

When Not to Choose Rubber Coating: Rubber coatings generally perform well up to about 120°C. For applications requiring continuous operation above this temperature, bare magnets or specialized high-temp coatings might be better options.

Industry Applications & Custom NBAEM Solutions

Rubber coated magnets from NBAEM are built for demanding industries where reliability matters. In the marine sector, our waterproof pot magnets are perfect for underwater ROVs, providing IP67/IP68-rated protection that keeps them fully operational even in harsh saltwater environments. For automotive uses like ADAS sensor mounting, our anti-slip rubber coatings ensure secure, scratch-free fixing that won’t shift or damage delicate surfaces during assembly or on the road.

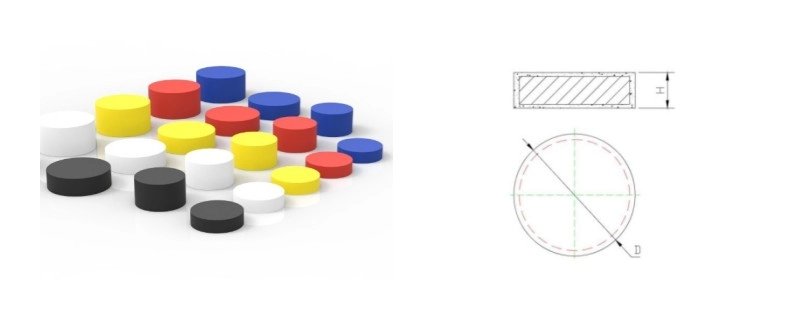

In renewable energy, our magnets stand up to the vibration and stress in turbine blade monitoring, delivering consistent performance without fatigue. Plus, NBAEM offers a variety of custom shapes and fittings — including D43 and D66 diameters, as well as internal and external thread options — tailored to fit your exact application needs.

If you want to explore how durable, high-grip rubber coated neodymium magnets can transform your projects, check out NBAEM’s solutions designed for tough environments. For more insight into neodymium magnet uses, including in complex electronics, see our detailed guide on the NdFeB magnets .

Technical Specifications Buyers Must Verify

When choosing rubber coated magnets, pay close attention to key technical specs to ensure performance and durability:

- Coating Thickness: Standard is 1–2mm, providing solid protection without adding bulk. Avoid coatings thinner than 0.8mm as they tend to peel or chip.

- Adhesion Quality: Check for compliance with ASTM D3359 tape test for strong rubber-to-magnet bonding.

- Pull Force Derating: Be aware that magnetic strength drops at temperature extremes—verify manufacturer data for acceptable operating ranges.

- REACH & RoHS Compliance: Essential for EU markets to confirm materials are free of hazardous substances and meet environmental regulations.

| Specification | Typical Value/Standard | Importance |

|---|---|---|

| Coating Thickness | 1–2 mm | Ensures durability & grip |

| Adhesion Test | ASTM D3359 | Confirms coating bond |

| Operating Temp Range | Usually up to 80–120°C | Affects pull force & longevity |

| Pull Force Retention | Check derating curves | Critical for load applications |

| Compliance | REACH / RoHS | Required for EU distribution |

Verifying these specs helps prevent failures like coating peel or unexpected force loss that could compromise your project. For detailed product info, check out NBAEM’s magnet assembly solutions, tailored for reliable performance across industries.

Procurement Red Flags & How NBAEM Delivers

When sourcing rubber coated magnets, watch out for thin coatings under 0.8mm. These often peel or crack under shear stress, compromising corrosion resistance and grip. NBAEM avoids this problem by applying a robust 1–2mm thick rubber layer that sticks tight even in tough conditions.

To speed up your product development, NBAEM offers a 72-hour express sampling service and an innovative 3D-printed prototype program. This means you can test exact magnet designs faster and reduce time-to-market.

Plus, NBAEM supports smaller orders with minimums as low as 100 pieces, unlike many suppliers that require 1,000+ units. This gives you flexibility if you need limited runs or customized batches.

For reliable rubber coated neodymium magnets with strong surface protection and procurement ease, NBAEM stands out as a trusted partner. Explore more about different magnetic materials on NBAEM’s detailed magnetic materials page to find the perfect fit for your application.

[…] though they do require protective coatings to prevent corrosion. Precision-engineered magnets, like NBAEM’s corrosion-resistant NdFeB magnets, extend lifespan and reliability in demanding audio […]