Project Description

Lamination core

NBAEM high-performance permanent magnet products have a wide variety of applications, from electric motors on ships, aircraft and motorsport vehicles, to pump couplings, batteries, solar panels and NMR Equipment. Our diverse markets allow us to keep our technologies on the leading edge of innovation. Our custom magnet production and fabrication ensures that our customers receive magnet products that are specifically catered to their unique design requirements.

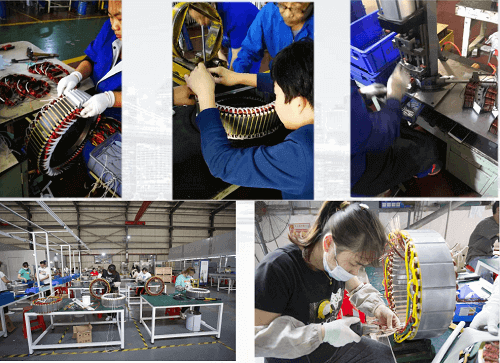

Lamination stacks are often used as stators or rotors in generators or electric motors. They can also be used as laminated cores. Lamination stacks are often made with nickel-iron or cobalt-iron materials to optimize costs and wear resistance. Both nickel- and cobalt-based materials are ideal for lamination stacks because they perform well in critical, heavy-duty applications, such as automotive, aerospace, and military settings.

Once you decide on an alloy, the laminations are laser-cut, notched, or stamped for precision, depending upon volume. Stacking fixtures are made to hold the laminations, which are then stacked to the correct height, with a tolerance of +/- 1 lamination. Precision gauge pins align each stack with accuracy up to +/- 0.0001 inches. Once the laminations are placed onto a stacking fixture, the laminations can be welded, riveted, or bonded together, depending on the application.

What Are Some Benefits of Using Lamination Stacks?

Our cobalt and nickel-iron laminations can be as thin as 0.2 mm thick. This dimension is important because thinner layers have better resistance to eddy current losses. Without lamination stacks, eddy currents can generate so much heat, causing poor performance and potential motor failure.

NBAEM ensures strict quality control, from raw materials through ready-to-use stacks. Our lamination stacks are essential elements in generators for aerospace, defense vehicles, medical devices, guidance systems and more. We help you customize your lamination stacks based on the specific materials or limitations required by your application. We can also create prototypes for your approval before mass-producing them for your project. Additionally, we offer a variety of machining options through our Grinding Department.

Reliable, High-Quality Lamination Stacks from NBAEM

Lamination stacks are vital components in electric motors, generators, vehicles, and other electromechanical systems.

We have years of experience producing lamination stacks for a variety of applications. We would be happy to work with you to find the best type of lamination and stack to fit your needs. If you’re ready to begin, contact us today or request a quote.

Lamination Core products

Generator lamination

Wind power generator stator lamination and High efficiency generator stator lamination

Servo motor core

Servo motor stacking rotor lamination and Servo motor stacking stator lamination

Electric Vehicle motor core

0.2mm high precision segment stator and self-bonding in-wheel motor core

Axial flux motor

An Axial Flux motor is unique type of electric motor that minimizes the gap between magnets and coils.

High Efficiency Motor Core

USED for Asynchronous motor, Outer diameter of stator is 100~980mm, Equivalent to IE3, IE4

More Motor

Includes Linear Motor, DC Motor, Switched Reluctance Motor

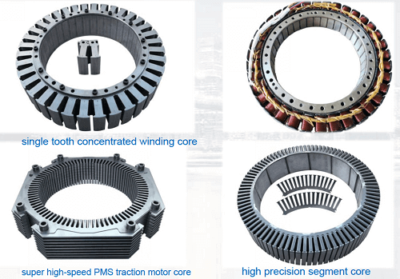

Elevator traction motor Core

- Single tooth concentrated winding core: the single tooth structure can maximize the use of the material and improve the material utilization, and save the cost

- Super high-speed PMS traction motor core: Outer diameter of stator is 400-500mm

- High precision segment core

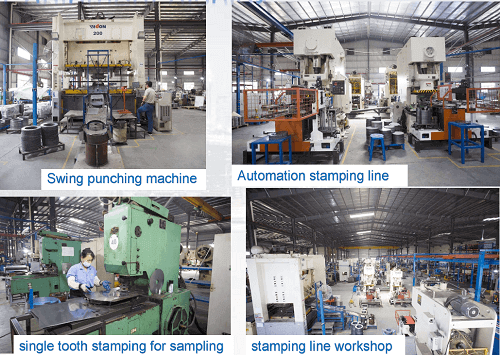

Lamination Core Production Workshop

Our Tooling ability & Molds management

We have our own R&D and design team, to make the rotor & stator in perfection. Furthermore, by manufacturing the molds by ourselves, the accuracy, cost and efficiency are highly guaranteed.

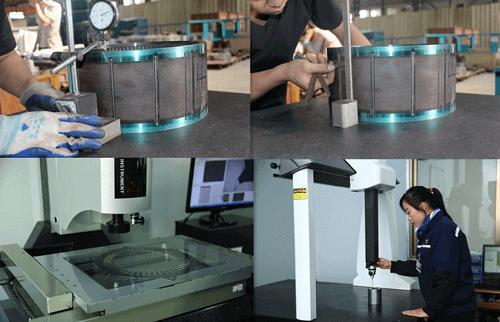

Our Quality control

Various inspections throughout the production process and tests performed on the parts ensure the utmost reliability and quality.